Among all the industrial automated systems, robotic arm grippers are mostly applied in material handling activities. Take sorting sheet metal cut parts for example, with a custom magnetic gripper equipped, factories’ sorting activities can benefit a lot from robotic system.

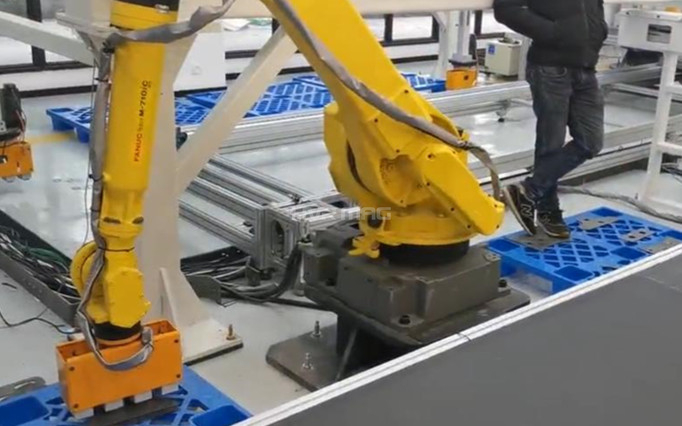

HVR MAG engineered robotic arm gripper, utilizes magnetic clamping technology, for the unloading and palletizing of sheet metal parts in a factory sorting system. In order to be able to manage pieces that vary in shape and size, the system is equipped with robot gripper(magnetic), which turned out to have increased the speed of the entire unloading and sorting process.

It picks up metal parts from a conveyor instantly, transfer and stack them respectively on the pallet - metal parts of same shapes in one stack. Undoubtedly, this helped speed up production and reduce labor costs.

Traditionally, sorting is carried out manually, due to the extreme variability of pieces, but it has very low added value. Needless to say, accuracy of placement, is hard to achieve in that way. This is all different with the application of

robotic arm grippers in automated sorting system. Repeat-ability, and precise positioning on palettes, facilitate the automation of industrial manufacturing processes.

Learn more about our gripper applications, please go to our

product detail page.