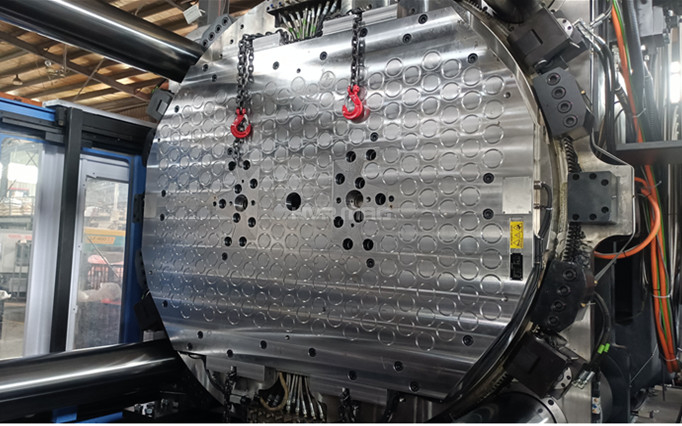

Check the new application of HVR MAG’s quick change mold clamp in injection molding - rotary magnetic plate installed on 1900 ton dual color machine, manufacturing plastic hardware pieces.

Why we recommend magnetic clamping over hydraulic clamps?

✦More Uniform ClampingTraditional clamping, like hydraulic clamps, focuses the clamping forces around the peripheral edges of the mold. HVR MAG’s magnetic clamping generates clamping force over the entire surface of the mold. Once the mold is magnetized it is nearly a “part” of the machine platen. This increased rigidity equates to higher quality parts, increased repeatability and less maintenance of the mold.

✦More FlexibilityMolds of any shape and size can be clamped without modification.

But you need to inform us the maximum and minimum size of molds of your injection molding machine, so that our engineers can design a suitable quick change mold clamp for your machine.

Ohter benefits of our quick change mold clamp plate, please go to our product page for more info.

Work directly with our experienced team to solve your toughest engineering challenges