Traditional die change processes in stamping operations often involve significant downtime, reducing overall productivity. Magnetic quick die change system is a solution that eliminates the time-consuming task of bolting dies onto a press, allowing for a seamless changeover in just minutes.

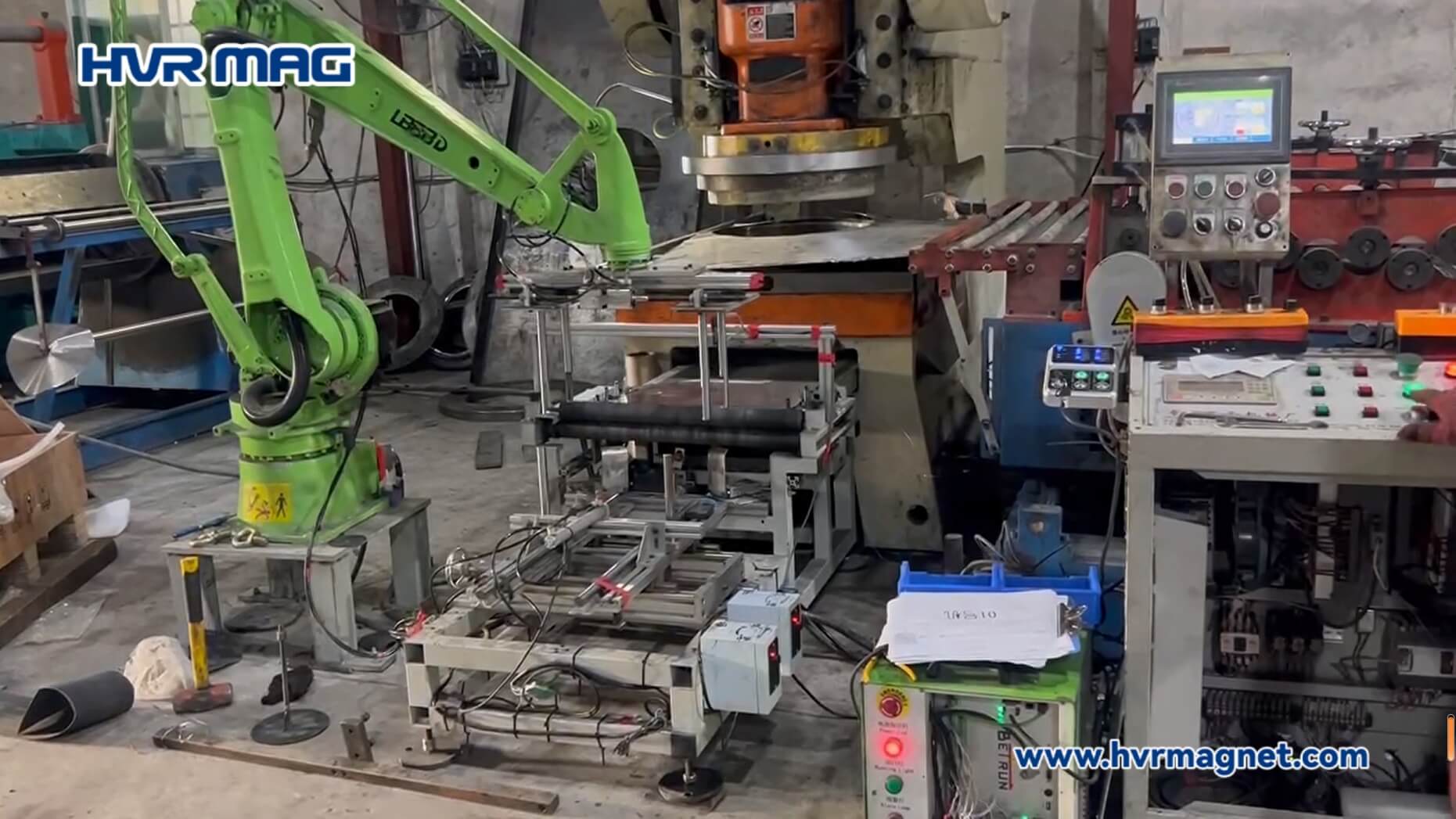

Our system harnesses the power of electro-permanent magnets to securely fix stamping dies in place. With a magnetic attraction force of up to 400 kg per small magnetic pole, this system ensures robust stability during the stamping process. For our client's circular bolster plate setup, the upper die is secured using a circular magnetic platen, while the lower die features large blanking holes to prevent accumulation of stamped parts. This thoughtful design accommodates the unique needs of circular press beds.

By eliminating the need for manual bolting and ensuring quick changeovers, our magnetic quick die change system optimizes reduce mold change time to 10 minutes. Operators can focus more on production and less on setup, thereby increasing throughput and reducing costs associated with downtime.

Our customizable solutions ensure seamless integration and rapid die changeovers. For more information on how our magnetic quick die change system can transform your manufacturing processes, contact us at export@hvrmagnet.com

Work directly with our experienced team to solve your toughest engineering challenges