This case will tell you why using customized magnetic lifter to replace permanent lifting magnets in handling irregularly shaped metal plate cut workpiece.

Later they approached us to order a customized magnetic lifter to solve their handling problem, due to the following disadvantages of permanent magnetic lifters:

✦Poor safety: the workpiece tends to drop when being lifted by this device, which contributes the major reason why they turned to our battery operated steel magnetic lifter.✦Low handling efficiency: each loading or unloading cycle requires manually switching on & off to clamp on or release the metal piece; also manual separation of sheets is required to avoid picking up 2 sheets one time.

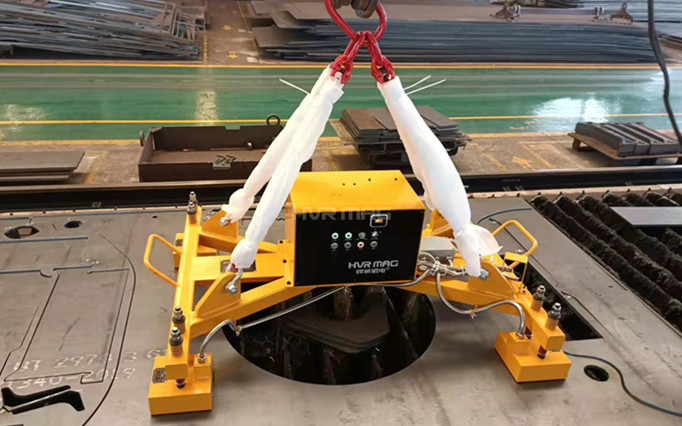

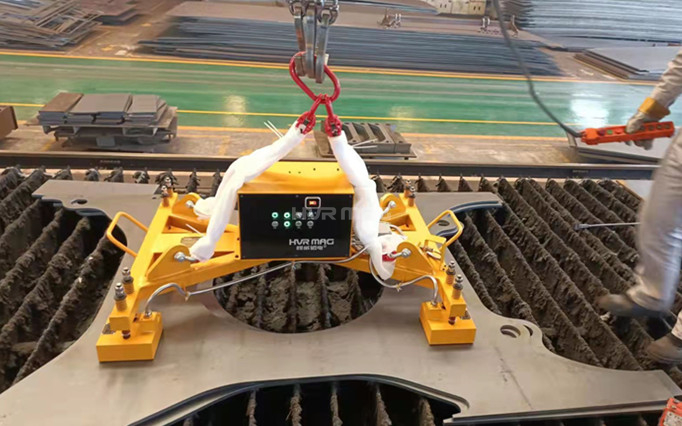

HVR MAG’s solution: tailor designed and manufactured magnetic lifting device, with four small magnet lifters mounted on each of the corners of the frame. The technology we’re using is electro permanent magnets, which consume no power during the lifting process.

Feedback from client after using our customized steel magnetic lifter:

✦Successfully eliminated the possibility of dropping load due to the property of this lift magnet & strong magnetic force;Have you encountered similar steel material handling problems? If so, you can get in touch with our specialist to order a customized magnetic lifter too, to assist you in the handling process. Or, visit our website to learn more about our magnetic lifting technology.

Work directly with our experienced team to solve your toughest engineering challenges