For factories or workshops where steel plates needs to be cut and handled frequently, automatic sorting and handling of the cut parts has a great influence on the overall efficiency of manufacturing process. That's where

magnetic end effector comes into play, in conjunction with robotic system.

The following scenario, is an epitome of magnetic end effector on cartesian robot in industrial automation, steel plate cutting and automatic sorting & handling workshop, in a domestic gantry robot manufacturing factory.

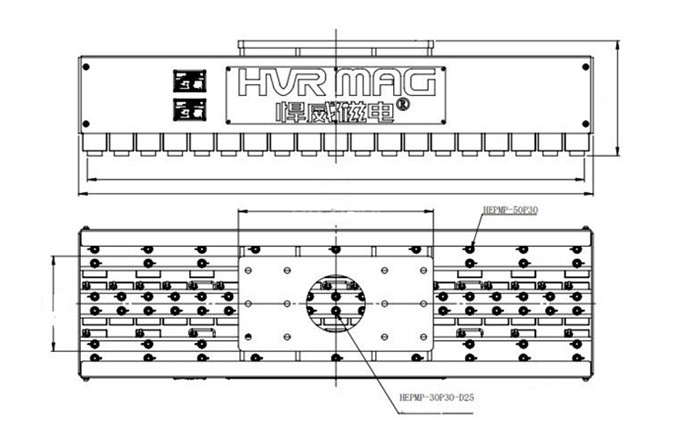

Magnetic end effector component: 36pcs of HEPMP-50P30 magnet gripper and 1 pc of HEPMP-30P30-D25 magnetic gripping head.

Rated gripping force: HEPMP-50P30, 50kg; HEPMP-30P30-D25, 10kg

For small piece of steel, one end effector is enough for the handling job; for large pieces, both of the two can be magnetized to grip and move steel parts. These magnetic gripping heads use their magnetized surfaces to grab ferrous items and workpieces.

Compared with manual handling, robotic pick and place not only improve the handling efficiency, but also can fit for the handling job of other steel parts. Learn more about the applications of magnetic end effector, please go to our

case section.