This case will show you how HVR MAG's

magnetic clamping plates works on 200 ton Haitian injection molding machine for quick mold change.

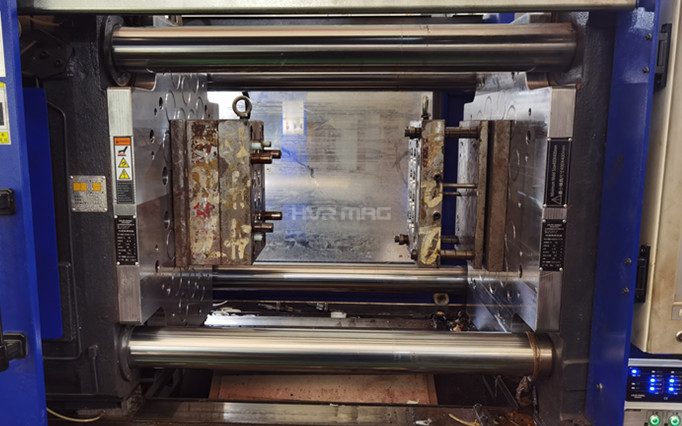

Mount these 2 magnetic platens on each side of the base plate of injection molding machine;

Then load the molds (movable/stationary) respectively, to continue subsequent injection molding process.

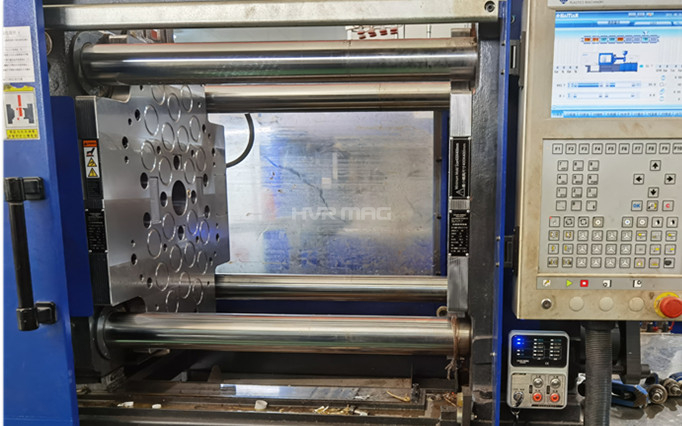

To change a set of molds for this 200 ton Haitian injection molding machine:

firstly

unload the existing molds - electrically demagnetize the magnetic clamping plates to release the mold;

Then,

load the new molds - electrically magnetize the platens to clamp the new molds.

Both the magnetization and demagnetization process can be realized via the interface panel, which is part of our magnetic mold clamping system.

Want to reduce your mold changing time from hours to minutes? Try our magnetic clamping plates, specifically designed for injection molding quick mold change.