In the realm of precision engineering and manufacturing, every step matters. It's not just about the tools you use but how effectively you leverage them. The double-sided electro permanent magnetic chucks are a solution that seamlessly integrates into various machining setups, enhancing both efficiency and precision.

Let's first grasp its operational principles.

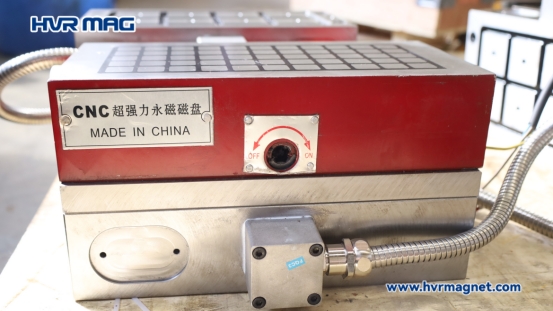

Begin by assessing the dimensions of the workpiece. Strategically arrange the chucks in a manner that maximizes coverage while avoiding interference with the machine's T-slots. Ensure that cables, junction boxes, and chucks are positioned within the workpiece boundaries to prevent any potential interference during machining. Once the chucks are positioned, connect all cable lines, reserving chucks with only incoming cables for the final setup. Rotate the switch to the "Down" position (corresponding to the chuck installation surface). Engage the air switch and set the controller's ship-shaped switch to "O." Press the "Magnetize" button on the controller. Upon successful magnetization, the green indicator light will remain illuminated. Verify that each chuck securely grips the machine's worktable.

Carefully position and secure the workpiece onto the chucks. Rotate the switch to the "Up" position (corresponding to the chuck working surface). Repeat the magnetization process. Ensure that each chuck firmly secures the workpiece. In cases where deformation may hinder proper adhesion, use a small iron piece to tap the area above the chuck's magnetic poles. A clear, crisp sound indicates secure adhesion. If necessary, apply additional pressure or repeat the magnetization process. However, if issues persist, assess whether the workpiece exceeds permissible deformation limits, as such instances are not conducive to magnetic machining. Upon completing the machining process, initiate the "Demagnetize" function on the controller. Once successful, the red indicator light will remain illuminated. Remove the workpiece and clean any debris from the chuck's magnetic surface to prepare for subsequent operations.

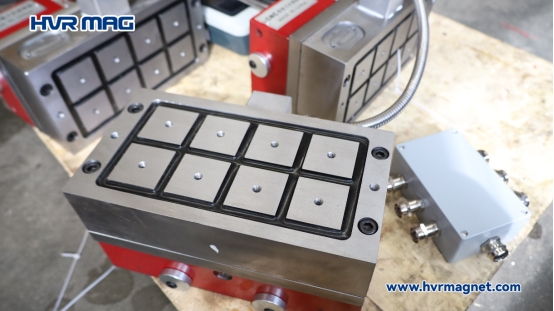

Our electro permanent magnetic chucks are engineered with a focus on modularity, rigidity, and strength. Designed and manufactured using state-of-the-art CNC machining centers, they guarantee superior performance and adaptability, even for high-precision machining tasks.

In conclusion, by integrating the double-sided electro permanent magnetic chuck into your machining workflow, you're not just streamlining operations but also elevating precision and efficiency to unprecedented levels. Experience the difference with HVR MAG's innovative magnetic solutions.