In industrial settings where efficiency, safety, and precision are paramount, the choice of equipment for material handling becomes crucial. Electro permanent lifting magnets stand out as a reliable solution, particularly for handling steel profiles like angle iron. Let's delve into the specifics of their application, benefits, and customization, drawing from a real-world scenario.

Each lifting scenario presents unique challenges. Some angle irons may require flipping during handling, necessitating a different approach. Thin-walled angle irons demand specialized considerations, potentially altering the magnet design. Additionally, factors like high temperatures or welding requirements mandate adjustments in magnet construction to ensure optimal performance and safety.

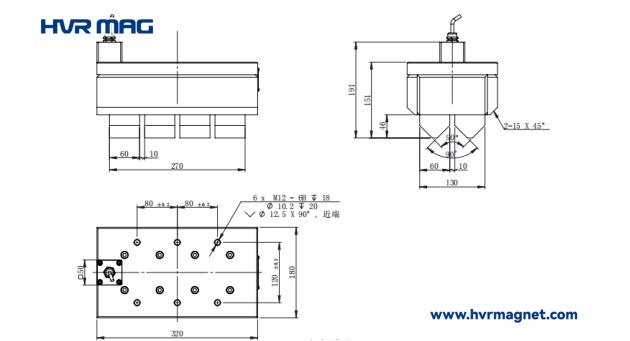

The customization process involves thorough analysis and simulation on computer systems. By simulating the client's operational conditions and requirements, potential challenges can be anticipated and addressed preemptively. This proactive approach ensures that when deployed, the lifting system operates safely and efficiently, meeting the client's needs with precision.

At every stage of the process, collaboration between HVR team and the customer is essential. By fostering open communication and active engagement, we ensure that the final solution aligns precisely with the customer's needs and operational realities. Whether it's discussing unique challenges, exploring customization options, or fine-tuning performance parameters, our collaborative approach maximizes satisfaction and results. For more information, please contact us at export@hvrmagnet.com

Work directly with our experienced team to solve your toughest engineering challenges