As a practical tool, the magnetic chuck in lathe machine is being understood and accepted by more and more manufacturers. However, customer enquiries have shown that there are still many questions about magnetic chuck. We have therefore compiled a list of frequently asked questions to help clear up any doubts you may have.

How the magnetic chuck in lathe machine works?

The EPM(electro-permanent magnet) magnetic chuck has 2 internal magnetic materials. They are Neodymium Iron Boron and Alnico. They work together on the workpiece when being magnetised. They use the electric current changes the internal magnetic circuit to form a magnetic suction force. The magnetic force can up to 16kg/cm² and holds the workpiece firmly on the machine tool. And the magnetic force does not decrease after the power is turned off, so no more power is needed after the workpiece is adsorbed.

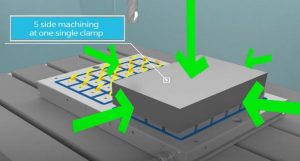

When you need to remove the workpiece, simply reconnect the power. Let the current change the direction of the magnetic field to complete demagnetisation. As a machining fixture for metal cutting (including turning, milling, grinding, planing, drilling, etc.), it is suitable for both general machine and high-precision CNC equipment. And because the magnetic chuck in lathe machine only attach to the underside of the workpiece, you can achieve 5-sided machining.

Will an electro-permanent magnetic chuck cause magnetisation of the insert?

Many people are concerned about the possibility of magnetisation of the insert. Which could affect chip removal from the workpiece or wear the insert. There is no need to worry. The standard permeability depth of HVR MAG‘s magnetic chuck is 13mm to 18mm. Even if the thickness of workpiece is less than the above, the magnetic field strength will not be very high and will not magnetise the insert. However, if the work piece is particularly thin for special machining, there may be poor chip evacuation resulting in the tool striking.

What about residual magnetism after machining?

Medium and low carbon steel has almost no residual magnetism. High carbon steel may has some effect. If required, our magnetic chuck can be designed with a demagnetising function.

Can machining deformation be avoided by using magnetic chuck in lathe machine?

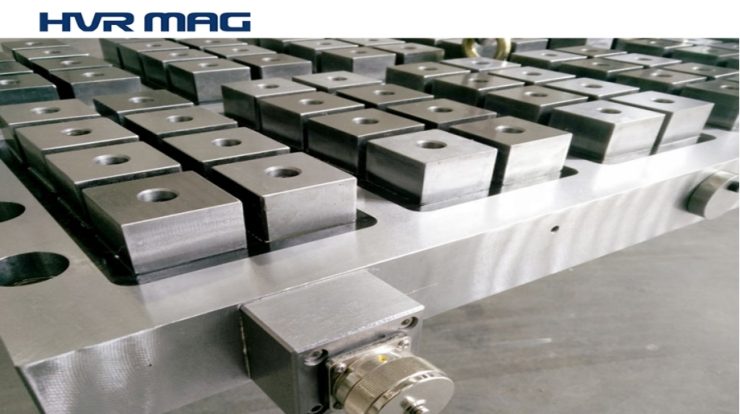

Our magnetic chuck in lathe machine with special floating magnetic block for the uneven surface of the workpiece can avoid machining deformation.

Basically, the magnetic chuck will not affect the machining result usually. We’d love to help if you are searching for a suitable magnetic chuck. Please feel free to contact us at:export@hvrmagnet.com