In this blog, you’ll learn why some cranes have two hooks, while some have only one, and the two-hook overhead bridge crane lifting device for steel plate/profiles/beam blanks.

First, let’s find out what the hook on a bridge is called?

Lifting hooks are used for grabbing and lifting loads by means of a crane or hoist. Lifting wire rope sling, chain or rope that is attached to a lifting hook should have a safety latch on it to prevent it from being disengaged.

Then, Why Do Some Cranes Have Two Hooks?

Not all cranes have two hooks. Depending on the specific construction requirements and the structure of the equipment itself, some cranes are equipped with two large hooks.

Double hook cranes are generally large tonnage, a main hook, a secondary hook, double hook cranes can work with two hooks at the same time to maintain the balance of the lifted weight, but also a single use of work, small tonnage on the small hook operation, saving resources.

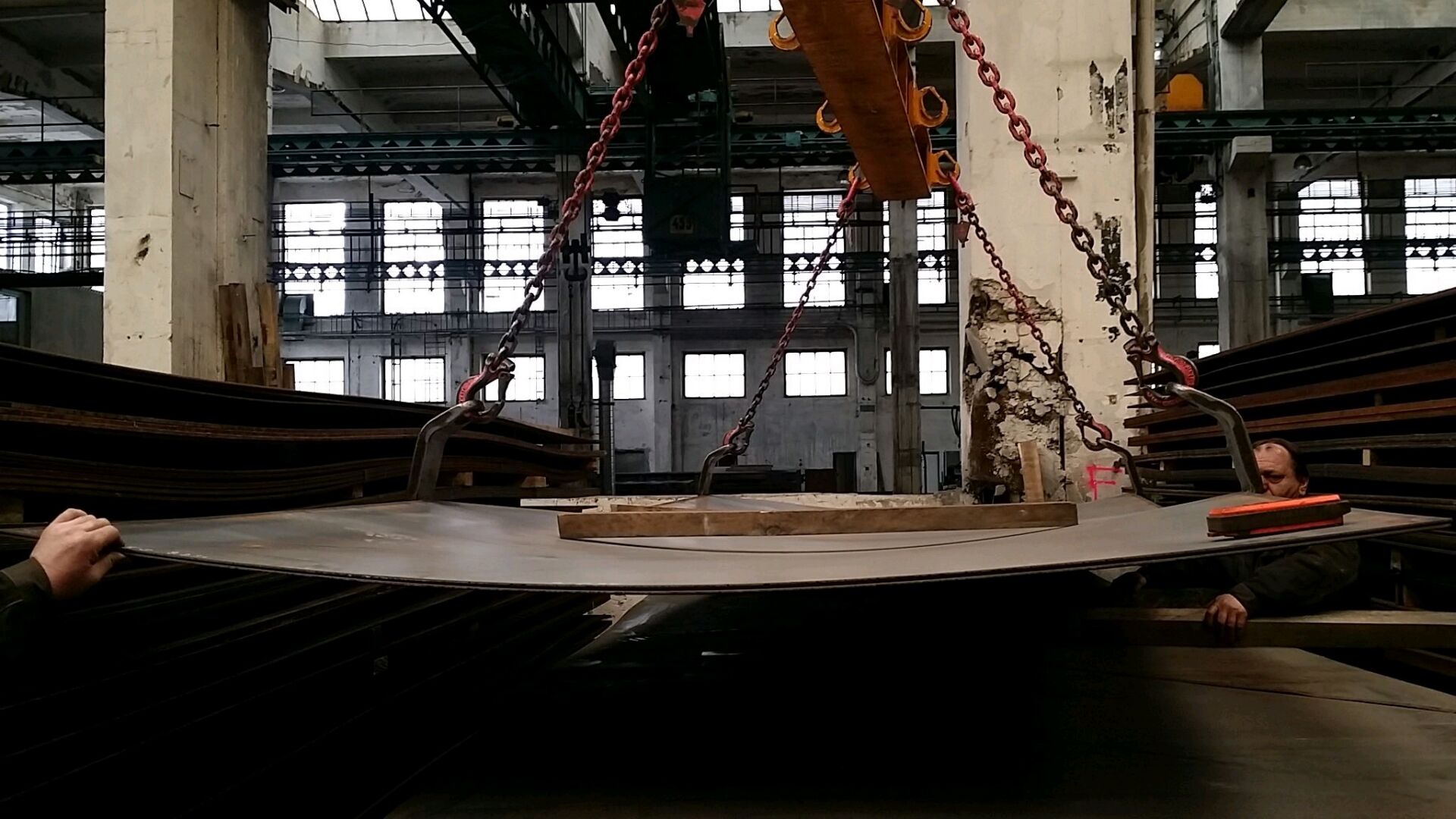

Two-Hook Overhead Bridge Crane Lifting Device for Steel Plate

The two-hook magnetic lifting device is better than the single hook crane lifting device in handling large heavy steel plates in performance, that’s because the latter tends to shake up and down during the moving and transfer process of plate. While the former type, is more stable and smooth in the process.

Of course, the design of this magnetic type of crane lifting device, is based on the feature of client’s crane, like its maximum lifting capacity, whether it’s single-hook or two-hook. HVR MAG can tailor design and manufacture lifting magnets for each type of your overhead crane.

Some may wonder using the crane lifting hooks/clamps can also get the job done. It’s true, but in a different way with lower handling efficiency. Lifting plate with clamps requires 2-3 workers to manually separate the steel plate and to assist the clamping and transferring process. Moreover, the plate lifted by clamps tends to deform and drop during the moving process, which is a huge safety hazard to the personnel and facilities.

With remote controlled magnetic crane lifting device, only one worker can manipulate the whole handling process. Once magnetized successfully, it can pick up the plate automatically and hold, transfer the plate in a more smooth, stable and safer way.

Moreover, you don’t have to worry that the heavy plate might fall off if the power supply suddenly goes off as our magnetic crane lifting device can remain holding of the plate.

Two-Hook Overhead Bridge Crane Lifting Device for Steel Profiles

Other than metal plates, we’ve also done two-hook crane lifting device for the handling of steel profiles, beam blanks.

The shape and the lifting force of each magnet lifters, distributed on the lifting beam, are specially designed according to the specifications of the load to be handled.

For use in places where power supply is unavailable or restricted/limited, we can also provide battery operated lifting magnets system for your crane.

HVR MAG can engineer 500kg-40ton crane lifting device for picking and moving a very specific ferrous load due to its size, shape, or center of gravity, from steel plates to profiles, beam blanks, slabs, billets, coils, etc. Contact our specialist to customize a magnetic lifting solution for your steel material handling needs.