When choosing a proper magnetic lifting device, some steel workers may have such queries like, what’s the minimum thickness of steel that lifting magnet can lift? Well, here, magnetic lifter manufacturer HVR MAG, will answer the question from different point of views.

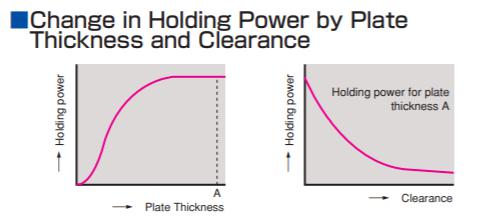

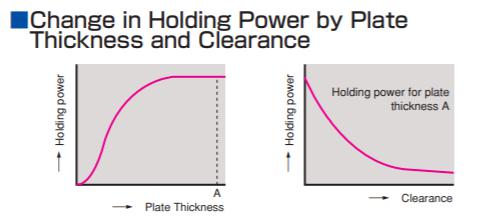

First of all, we need to know that the lifting capacity of lift magnet could vary depending on the load(material) thickness, surface condition, shape and material of object to be handled.

The magnetic flux of magnetic lifters requires a minimum material thickness. If the workpiece does not reach this minimum thickness, the holding power(lifting force) is smaller. For larger lifting benefits greater material thicknesses are required.

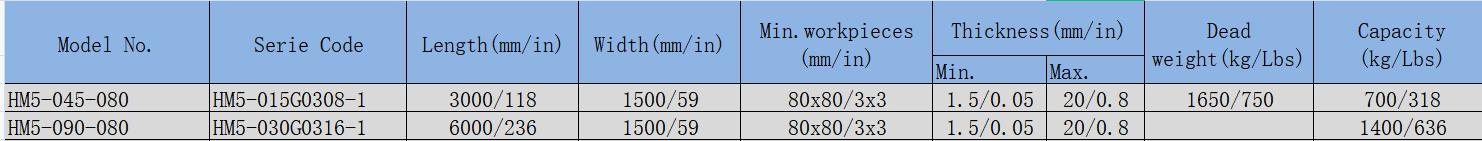

The thickest steel plate/sheet that HVR MAG’s magnetic lifting system had handled is 1.5mm. The HM5 Series, cutting table magnets for fast and efficient loading & unloading of sheet on any type of cutting machines (plasma, oxyacetylene, laser), specially developed to remove cut pieces, including residual material, from the cutting table in one movement.

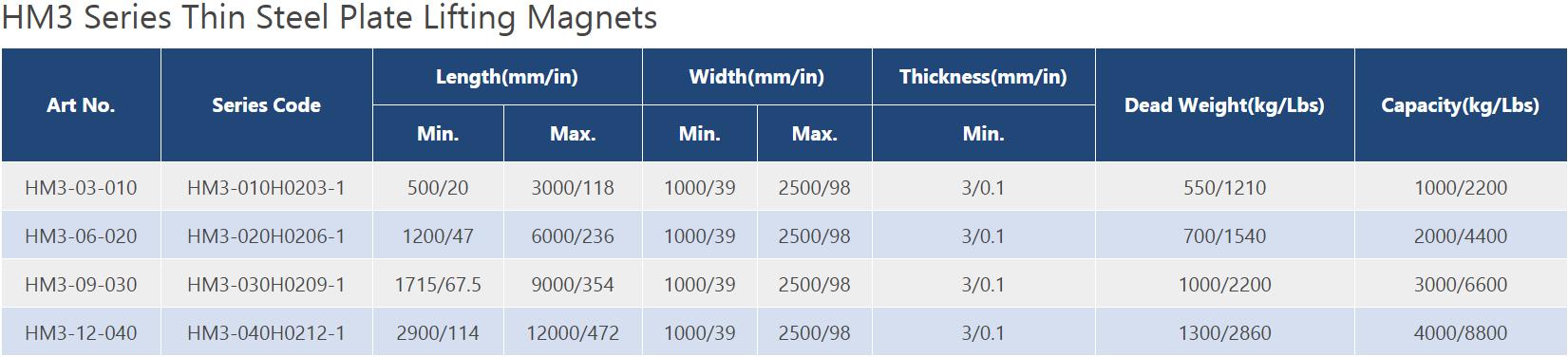

HM3 Series Thin Steel Plate Lifting Magnet is designed for lifting thin steel plate with a minimum thickness of 3 mm.

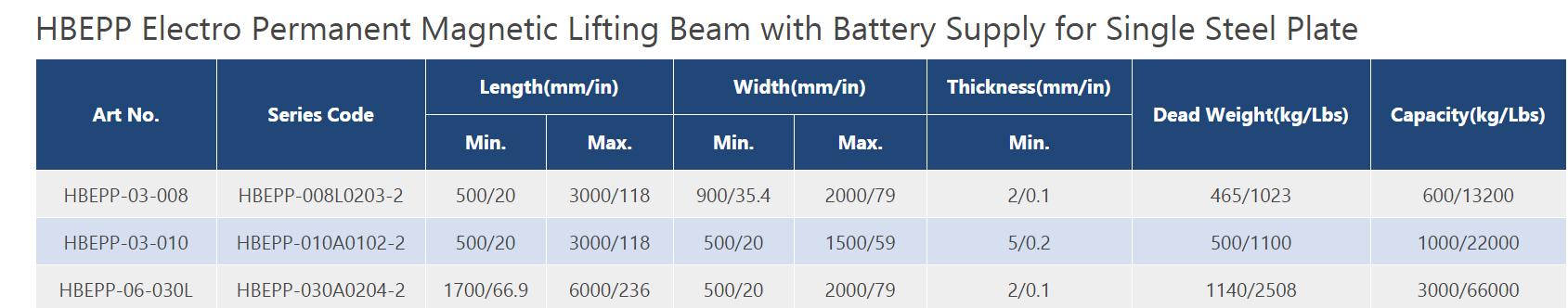

HBEPP Series battery powered/operated lifting magnet, for steel lifting operation in areas where power supply is unavailable, the minimum thickness of plate is 2mm.

What needs to be pointed out is that the minimum thickness of steel mentioned is for uniformly shaped steel material. For unevenly structured steel, the lifting capacity of lifting magnet shall be specifically designed and engineered per your material specification and handling requirement. HVR MAG provides customized magnetic lifting solution for various steel industries.