Permanent Electromagnet in Steel Shot Blasting

As a supportive equipment, permanent electromagnet has played a great role to complete the steel shot blasting link efficiently.

What is Steel Shot Blasting? It is an abrasive descaling process that removes surface level debris resulting in enhanced material condition. This process effectively strips steel plate products containing rust or mill scale. It’s the first step of steel pre-treatment which improves the quality and added value of steel produced by steel mills. Especially in the construction of ships, drilling platforms and other offshore engineering projects, high quality standard and accuracy of the steel size is requested. A considerable challenge faces for various surface treatment work in large quantities.

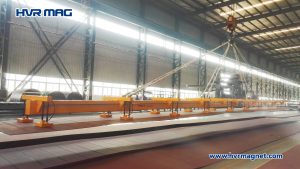

As indicated, a lifting magnet is working on a steel shot blasting line. In order to avoid the collision to the material, a cross-type conveying system is functioning in the loading and unloading area of the plate shot blasting machine, allowing the materials to transfer continuously and effectively.

How does a Lifting Magnet Work?

The permanent electromagnet lifter relies on strong magnetic suction to absorb the surface of the steel plate. It needs 2-3 seconds of pulse current to activate the magnets. After that the permanent magnets keeps the suction force under control, no extra electricity power needed.

As shown, the long machine on the left of the picture is the shot blasting machine. Our lifting magnet is handling a piece of about 22.5 meters long, 4 ton rusty steel plate to the centrifugal push wheel table. After finishing blasting, the steel plate is moved to collection area for further production. With the help of overhead crane, the lifting magnet’s busy in loading and unloading section moving flexibly in the whole workshop over 10 meters high.

What Materials can be Lifted by a Lifting Magnet?

Any ferrous material can be handled by a lifting magnet,these include, but are not limited to:

steel plates

Steel Coils

Strips

Profiles

Pipes

Billets

Round bars

Rails

Is Permanent Electromagnet Lifter Safe?

Absolutely yes! A complete system ensures the most safety issues:

*EMPs technology independent of the electric current = 100% safe, Safety Factor 3:1

*Simultaneous 2-button operation to deactivate/demagnetize.

*Lamp block for indication of the status of the magnet.

*Both Manual & Radio Remote Control which prevents the operator from getting close to the load, ensure most labor safety.

*No damage and surface deformation caused to the steel.

The lifting magnet for the steel shot blasting plate is of great help for the customer. It’s designed and manufactured by HVR MAG, who is one of the world’s most reliable forces in industrial magnetic equipment with strong innovative team group. If you want this product to boost your production, please don’t hesitate to get a quote & contact us at export@hvrmagnet.com, we’ll be happy to assist you!