The steel plate lifter is a very useful tool for handling steel plates. How do we choose between the different types of steel plate lifters?

First of all, let’s look at the classification of steel plates.

Thin steel plates are usually those with a thickness of less than 6 mm, which can be easily deformed. The deformation of medium and thick plates with a thickness of more than 6 mm is not obvious. Secondly, let’s see if the surface of the steel plate is smooth. A smooth surface and a rough surface can be used with different steel plate lifters.

Now let’s look at the different types of steel plate lifter.

Lifting magnet

The lifting magnet is the most suitable steel plate lifter. The flat surface of the magnet does not leave scratches when handling thin, smooth steel sheets. Whether it is a steel plate, a steel pipe or a coil, the magnet will hold the steel as long as there is sufficient contact area. Industrial lifting magnets are also very easy to operate. HVR MAG’s electric permanent magnet lifting magnets can be remotely controlled so that even a 40 tonne steel plate can be easily lifted by one person.

Hooks and clamps

Conventional hooks and plate clamps are very cheap and can lift not only steel plates but also other materials. However, it is very easy to drop material due to an unstable structure. At the same time, hooks and clamps are very prone to scratching steel plates. The use of hooks and clamps requires workers to manually position them, which is very labour intensive when handling larger and heavier steel plates. As a result, hooks and clamps are being phased out in favour of new technology and tools.

Hydraulic steel plate lifter

The electro-hydraulic steel plate lifter can be seen as an upgrade from the hook and clamp. It certainly works better because the caliper positions can be fixed on both sides and you no longer have to worry about the hook and clamp moving out of position. But it is still not convenient enough and still requires a lot of work from the operator. For example, when handling thin steel plates, padding or pallets must be placed under the plates to prevent the surface from being worn.

Vacuum lifter

When it comes to plate handling, the vacuum cups are designed for gripping or handling smooth, flat materials and can of course also be used as steel plate lifter. It is perfect for handling glass, plastic, etc. It is fast and does not wear the surface. However, the vacuum gripper is not very suitable for handling sheet steel. Most steel plates have a rough surface and may have contaminants such as metal chips or rust. This can wear out the rubber ring of the vacuum chuck and you are likely to spend a lot of time and money maintaining the vacuum chuck. Secondly, a vacuum chuck cannot grip sheets with drilled holes.

Tips for using magnetic steel plate lifter

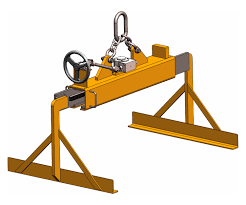

Lifting magnets must be adapted to your working conditions in terms of lifting capacity and size. If you need to lift several sizes of steel plate, you can choose a lifting magnet with a telescopic beam. The strength of the lifting magnet can be adjusted. The magnet module can be controlled in groups. The lifting range can be extended and a wide range of steel plate sizes can be accommodated. If you need to handle steel plates outdoors for long periods of time, you can choose an electro-permanent magnet lifter with batteries. The EPM uses only 95% of the power of an electromagnet, making it very energy efficient. This is because the EPM only uses electricity when magnetising and demagnetising.

When using a magnetic steel plate lift, centre the lifting area so that the overhang at the ends of the plate is approximately equal. This allows for better balance. It is also recommended that the overhang is less than 1 metre on one side when handling thin steel plates and less than 1.5 metres on one side for medium thick plates. Do not move quickly after picking up the sheet to avoid knocks and do not allow anyone to stand under the load. Check the cleanliness of the magnetic surface and the integrity of the connecting parts before each use.

The HVR MAG steel plate lifter is available in different series and models, the HM3 series is designed for lifting thin steel plates and the HM2 series with telescopic beam is designed for a wide range of plate lengths. If you need to turn steel plates, the HM4 series may be the product for you. Feel free to browse our product page and contact us.