The round magnetic chuck is a workholding device specifically designed for use on vertical lathes. The vertical lathe has a vertical spindle and a circular table for mounting the workpiece. The horizontal position of the table makes it suitable for machining heavy parts with large diameters and short lengths. The vertical lathe can machine internal and external cylinders, tapered surfaces, end faces, grooves, chamfers, etc. The workpiece is easy to set up and calibrate.

Before the advent of round magnetic chuck, vertical lathes used mechanical fixtures to clamp workpieces. This involved more clamping steps and was less efficient. Mechanical clamping also affected the machining stroke. HVR MAG is a specialist manufacturer of electro-permanent magnetic chucks. We have developed the DYCC series of round magnetic chuck specifically for vertical lathes.

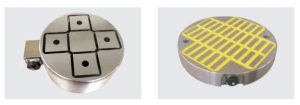

Introduction of the DYCC magnetic chuck series

DYCC1 round magnetic chuck for small (horizontal) lathes

This series is an electromagnetic chuck for small lathes and is particularly suitable for clamping small discs of magnetically conductive workpieces. The modular design ensures high suction power and easy clamping. The pre-magnetisation function facilitates the initial positioning of the workpiece. The low penetration depth (DYCC1-B series) makes it easy to clamp thin workpieces up to 4 mm thick.

DYCC2 round magnetic chuck for large (vertical) lathes (uniform suction type)

This series is suitable for use with vertical lathes, CNC 5-axis precision indexing machines, CNC 5-axis integrated cutting machines, etc. With its circular radioactive pole structure, it is suitable for holding round workpieces and workpieces of any shape. The workpiece can be in contact with all magnetic poles at the same time, with strong magnetic suction. Multi-magnetic circuit, electronically controlled design, 1-10 seconds for charging and demagnetising (depending on the size of the disc), adjustable magnetic force. No need to keep the power on after magnetisation, the connection cable can be disconnected by means of a quick-fit connector. Free rotation of the disc (also available with conductive slip ring mechanism, no need to connect and disconnect the quick connector). The workpiece can be freely clamped and machined from five sides. Short charging and demagnetising times, no heating of the coil. The absence of thermal deformation ensures machining accuracy.

DYCC3 magnetic chuck for large (vertical) lathes (incremental suction type)

This series is also suitable for use with vertical lathes, CNC 5-axis precision indexing machines and CNC 5-axis integrated cutting machines, etc. The unique design of the variable cross-section magnetic pole structure ensures that the suction force gradually increases as the outer diameter increases. The double magnetic circuit design allows the magnetic fields to be superimposed, and the T-slot design makes it easy to add a magnetic guide block (you can also make your own shaped magnetic guide block according to the shape of the workpiece suction surface, so that even if the suction surface is curved, it can be clamped well).

Advantages of DYCC round magnetic chuck

Fully open table

By eliminating the mechanism, the entire machine table can be used completely open. The part to be machined can even be larger than the machine table.

Optimised machining stroke

The fully open table not only extends the range of flat surfaces, but also does not affect the machining stroke.

Robust overall construction

DYCC discs are cut from a single block of steel for rigidity. The dimensions are designed to be compact. No moving parts inside the disc for high reliability and long life.

Quick clamping

To use the DYCC round magnetic chuck, simply place the workpiece in the correct position and switch on the power to magnetise it. The process is simple and easy to follow. The magnetisation process takes only a few seconds. Once magnetised, no further power is required and the connection cable can be removed via a quick release connector.

No deformation

DYCC discs not only clamp and release workpieces quickly, they also prevent them from deforming. The floating magnetic guide pad can automatically adjust to the shape of the workpiece clamping surface. The uniform clamping force solves the problem of machining vibration, bringing unparalleled benefits in terms of machining accuracy, tool life, chip removal and machining efficiency.

For more information about DYCC round magnetic chuck, please contact us at: export@hvrmagnet.com