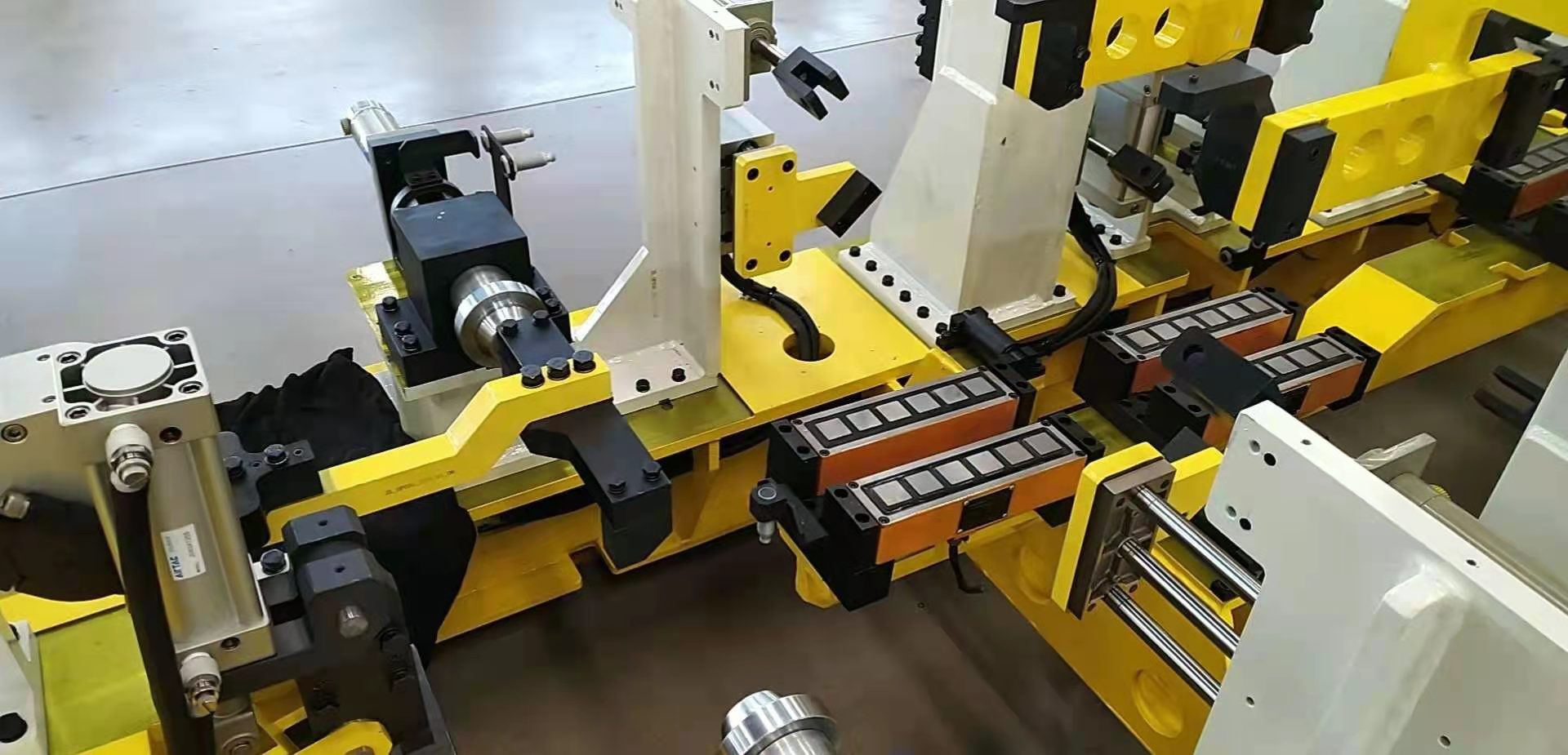

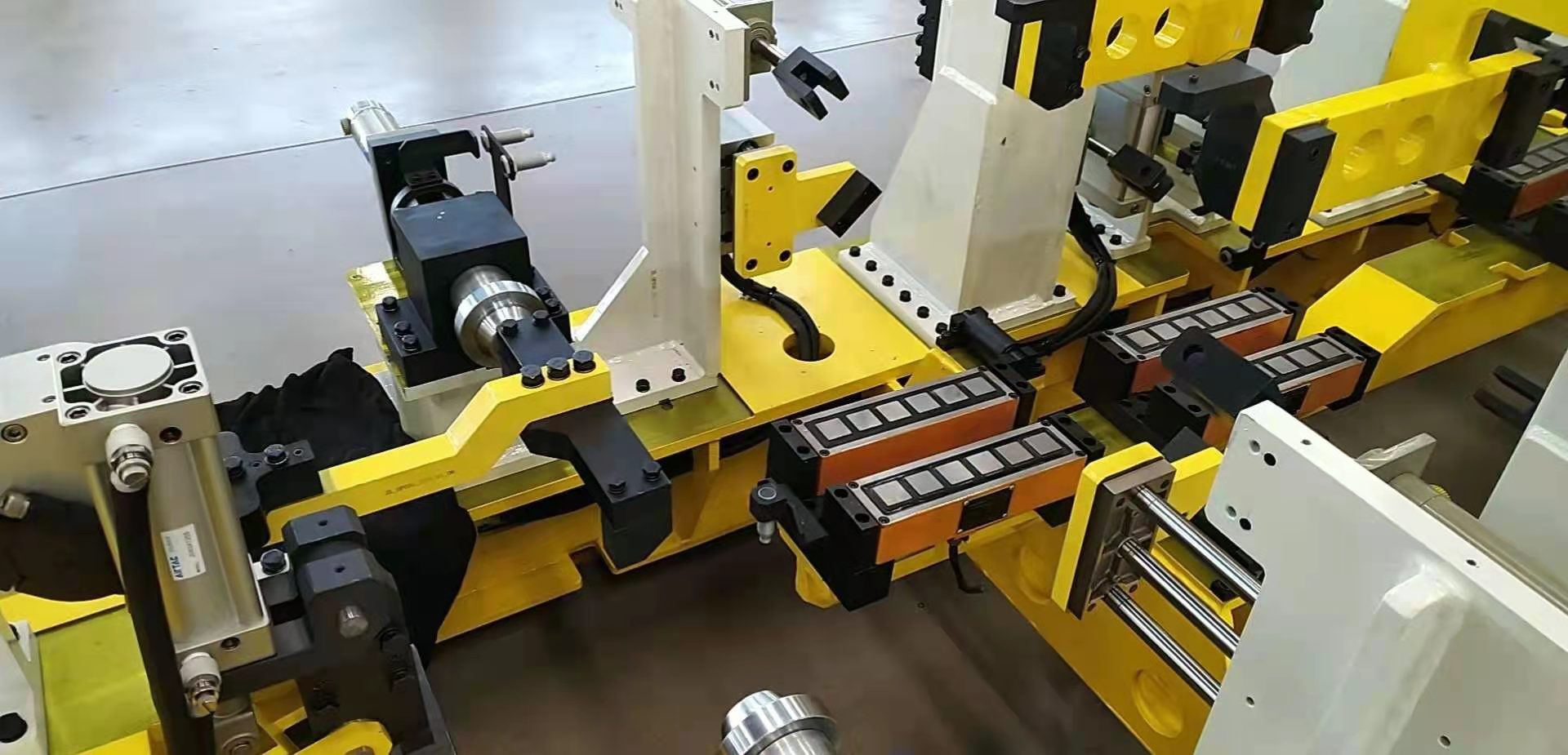

Here, we’re gonna introduce a new type of magnetic welding clamps – custom-made electro permanent magnets for workpiece clamping in robotic welding. They are essential auxiliary holding magnets in automotive welding assembly.

In automobile industry, automobile(car) welding fixture is a component which is important to auxiliary welding. The automobile body is welded by multiple complex sheet metal parts and other auxiliary work pieces. In this process, welding magnets play an important role in supporting robotic welding.

The magnetic welding clamps in the picture, are used as holding magnets with extremely strong magnetic fields that make great tools for the welding assemblies of car body in an automobile manufacturing factory. They are a special tool for holding a work piece in proper position during manufacturing operation, to replace hydraulic fixture and to optimize design for machine.

Why did they use magnetic welding clamps?

- To improve space utilization

- To facilitate designat a later stage – some positions can only use holding magnets

The body of a vehicle is made up of several hundreds of stamped components which are joined together by spot welding process, where welding magnets come into place to position product parts for welding. This secures the geometry of the product parts.

For supporting and clamping the work piece, and to locate and immobilize workpieces for machining, inspection, assembly and other operations, welding magnets and other welding fixtures can help increase productivity and reduce operation time for welding in the automotive industry.

In every production process where welding is necessary, high-quality, accurate magnetic welding clamps determine the quality of the final product.