Water heaters are becoming common in modern homes, providing us with hot water during the cold winter and ensuring a comfortable life for the family. Nowadays, more and more families are installing water heaters, so how is a water heater produced?

HVR takes you into the world’s top water heater A.O. Smith production line, to see the production of water heaters.

Generally, water heaters are cylindrical, producing the top cover on both sides of the cylindrical tank. The production is entirely mechanized and only requires workers to be on hand to keep a close eye on the production situation.

The tank body is produced by bending and forming a whole steel plate, with precision welding required to complete the intermediate joints. The flow line has a neat row of glossy boxes, both large and small, designed to suit different product models.

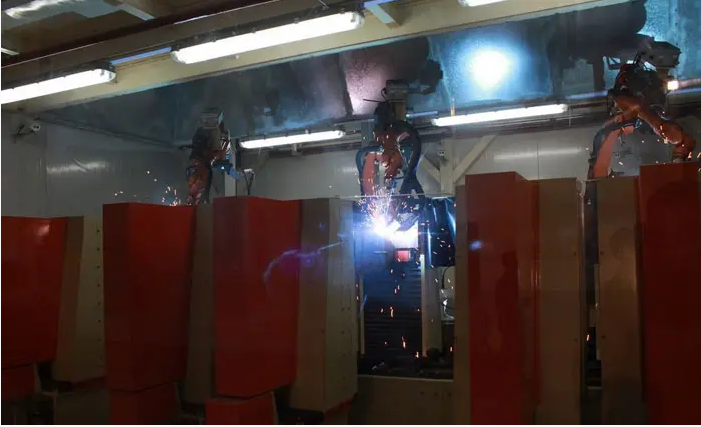

Fully automated welding robots complete the welding work, a modern feature of the A.O. Smith. And we don’t allow workers to enter this area to ensure production safety.

The painting process, which entails spraying the inner liner with A.O. Smith’s patented material, is a unique formula that only seven people know. An electro-permanent magnet lifts the liner to ensure the spraying process is carried out steadily.

The completed sprayed inner liner undergoes preliminary testing, and staff needs to wear special glasses to do the testing. We understand that the entire production process of an electric water heater requires at least 3-5 inspection procedures.

The welding of the top lid studs, which is also mainly done by fully automated robots, allows for quick switching between different models, and the welding quality is superb.

After the liner has been welded, it needs to be inspected in a special workshop, mainly using a helium inspection link derived from aerospace technology to check the quality of the robot’s welding. This is done fully automatically, with no human intervention required.

The subsequent assembly process is mainly done by hand, with a worker inserting components such as heating and anode protection rods into the inner liner. The inner liner is fitted into the housing, mainly done by hand because the work requires less skill.

Workers are doing the final assembly process, and the water heater is finished with production.

The product is packaged on the line, protected against shocks, etc., and labeled and boxed. The production line is tightly connected, and high-efficiency works to have a competitive advantage.

The warehouse is full of qualified electric water heaters and enormous output, and the shelves are full. Of course, before leaving the factory, these electric water heaters need final product testing to ensure product quality.

What can HVR do?

HVR offers the most competitive lifting magnets for water heater processing. Electrify your workflow and accelerate your automated processing. If you are interested in it, please feel free to contact us. We are always here to support you.