The magnetic gripper in robotics is a useful tool for handling ferrous materials. It relies on a smooth magnet surface to adhere to steel and is quick to grip and release. The magnetic gripper in robotics is often used to handle steel plates safely and efficiently. But it’s even more surprising when it comes to handling structural steels or pipes.

For example. One of our customer is a manufacturer of oil pipelines. They need to put the short steel pipes into packaging box. Before using the magnetic gripper in robotics, workers need to repeat the palletising cycle at least 20 times to complete the packaging of 80 short tubes. This was labour intensive and inefficient. With a custom-made square magnetic gripper from HVR MAG, the packaging of 80 short steel pipes can be completed in just one movement. This is something that vacuum grippers and mechanical grippers cannot do.

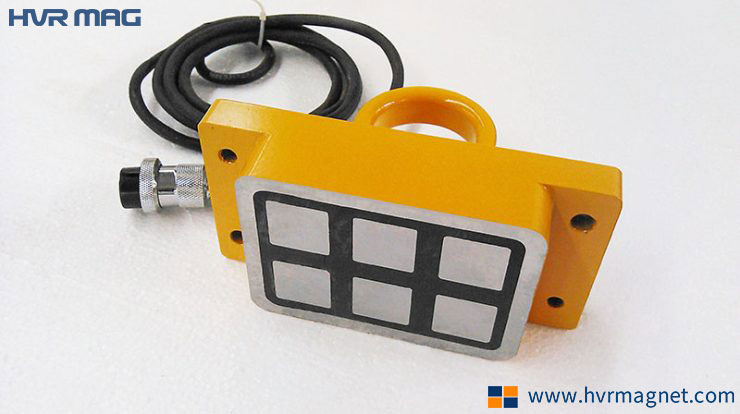

And when handling structural steels such as channel, the magnetic gripper in robotics that HVR MAG designed for the customer is very practical. As shown in the picture, the magnetic gripper consists of 7 groups of electric permanent magnets. Each group has two magnets that are responsible for gripping both sides of the channel to maintain balance. This magnetic gripper can grip 7 channels at a time, either in the recess or on a flat surface. The suction force of the electro-permanent magnet is very strong, up to 16 kg per square centimetre. The workpiece will not fall off even if it is turned over. Before using the HVR MAG magnetic gripper, this customer used a hydraulic gripper. Compared to the hydraulic gripper, the magnetic gripper is much simpler and lighter in construction.

Advantages of magnetic gripper of HVR MAG

- High efficiency and fast grip and release. The electromagnetic permanent magnet can be magnetised and demagnetised in 0.2-3 seconds.

- Energy saving, EPM uses electricity only when charging and demagnetising.

- Can grip different shapes of workpieces, with little restriction on the shape and surface of the workpiece.

- Low maintenance, making it a flexible and cost-effective option for manufacturers.

Precautions when using the magnetic gripper in robotics

- When gripping the workpiece, avoid collisions that may cause the workpiece to fall.

- Keep the magnetic attachment surface and the workpiece surface clean. A small amount of oil may reduce the gripping capacity.

- Workpieces with a high carbon content may have residual magnetism. An optional demagnetising function on magnetic gripper is recommend.

- Can only handle ferrous materials.

For more information, you can view our website or send your inquiry.