During the production, processing, and lifting of pattern steel, it is always inevitable that the pattern steel will be deformed or scratched. How to prevent the pattern steel from bending and scratching during lifting and handling? The electro-permanent magnetic lifter will give you the answer.

What is pattern steel?

Pattern plate is commonly used in pedestrian passages, such as steel staircases and aisle corridors. The raised pattern on its surface can increase friction and prevent pedestrians from slipping, and it is beautiful and easy to clean. Pattern steel sheets are widely used in shipbuilding, boilers, automobiles, tractors, train carriages, and construction.

Because of its raised edges on the surface, patterned steel plate has an anti-slip effect and can be used as flooring, factory escalators, work frame treads, ship decks, car flooring, etc. Patterned steel plates are used as treads for workshops, large equipment, or ship walkways and stairs and are steel plates with a diamond or lentil-shaped pattern pressed into the surface.

When lifting and placing the pattern steel, it is easy to scratch the surface. How do we improve lifting efficiency?

Clamps are avoided if the surface needs to be avoided from being scratched. Clamp handling is inefficient and prone to scratching the machined parts. It is also unsafe and can pose a safety hazard. The vacuum lifters are not very suitable for the handling of pattern steel. They are generally used for the transportation of objects with smooth surfaces. For objects with uneven surfaces, the vacuum lifters cannot be closely connected to the object’s surface and are easy to fall off when handling.

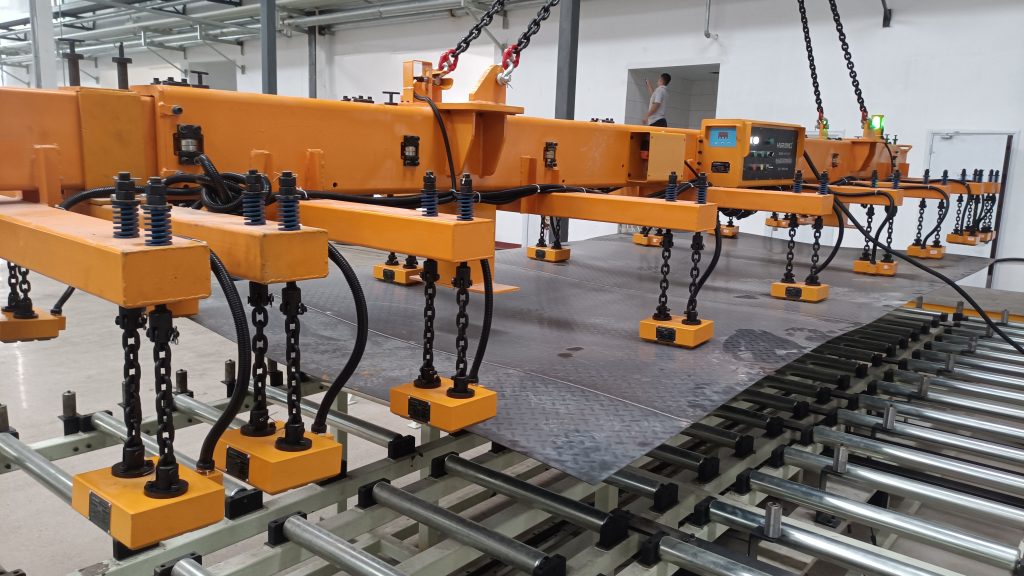

Therefore, HVR recommends the electro-permanent magnetic lifter to our customers, which has no special requirements on the working conditions. On the one hand, the intense magnetic force requires no power supply during processing. There is no thermal deformation, which effectively guarantees processing accuracy. On the other hand, the electro-permanent magnetic lifter does not require electrical energy during the working process. It only relies on the permanent magnetic force to hold the workpiece, avoiding the risk of the workpiece falling off due to the loss of magnetic force caused by a sudden power failure and damage to the disconnected wires of the electromagnetic system. It produces a safe, strong, and efficient force without using any energy, both economical and environmentally friendly.

HVR engineers can design and install our electro-permanent magnetic systems based on the particular needs of your company’s unique application. Contact us for more information.