Lifting magnets are used to lift and transport heavy objects using magnetic forces. They are commonly used in industrial settings where heavy materials need to be moved quickly and efficiently. One type of lifting magnet that has gained popularity in recent years is the electric permanent lifting magnet. Let’s see the working principle of EPM lifting magnet and lifting magnet applications in various industries.

Working principle of Electric Permanent

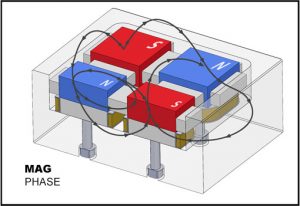

The magnetic field of EPM comes from the two permanent magnetic materials inside. The electric current only acts as a controller of the magnetic field. When magnetising, the current causes the internal Alnico magnets to change the direction of the magnetic field. The magnetic fields of the NdFeB and Alnico magnets then act together on the workpiece to attract the steel. The suction force of an electro-permanent magnet is very strong, up to 16 kg/cm². And the magnetic force does not require an electric current to maintain magnetism. During demagnetisation, the current causes the magnetic field direction to change again. Then the magnetic field on the pole surface disappears and the load is automatically released. Based on the working principle of the electro-permanent magnet, we can see the advantages: energy saving, safety, powerful and ease to use.

Benefits of Using Electric Permanent Lifting Magnet

High Lifting Capacity: Electric permanent lifting magnets have a high lifting capacity, making them suitable for lifting heavy objects that are difficult to move with other types of lifting equipment.

Efficient Operation: Electric permanent lifting magnets are easy to operate and require minimal setup time, allowing for efficient and quick lifting and transportation of heavy objects.

Improved Safety: Electric permanent lifting magnets are designed with safety in mind. They have a built-in safety factor that ensures the load is held securely during lifting, reducing the risk of accidents or damage to the object being lifted.

Cost-Effective: Electric permanent lifting magnets are cost-effective as they require minimal maintenance and have a long service life. They also reduce the need for manual labor, which can save time and money.

Electric Permanent Lifting Magnet Applications

Manufacturing Industry: Electric permanent lifting magnets are commonly used in the manufacturing industry to lift and transport heavy metal plates.

Construction Industry: Electric permanent lifting magnets are also used in the construction industry to lift and transport structural steel such as H beams, round bars and tubes.

Shipbuilding Industry: Electric permanent lifting magnets are used in the shipbuilding industry to lift and transport heavy steel plates and sections.

In short, EPM lifting magnets can be used in all situations where large steel has to be handled or lifted. Because it is strong and safe enough, there is no limit to the lifting height. You can also choose a model with a telescopic beam for multi-size steel handling tasks.

Conclusion

Electric permanent lifting magnets offer a safe, efficient, and cost-effective solution for lifting and transporting heavy objects in various industries. Their high lifting capacity, efficient operation, and safety features make them a popular choice for many industrial applications. If you are looking for a reliable and efficient solution for lifting and transporting heavy objects, an electric permanent lifting magnet is definitely worth considering.

HVR MAG is available in a wide range of models and series of electro-permanent lifting magnets. Whether you need to lift steel plates, structural steel or automated loading and unloading, we will be able to design the most suitable lifting solution for you. Welcome to contact us.