The topic today will take you to the CNC vertical machining center in a rocker arm manufacturing workshop, to see and learn more about electro permanent magnetic chucks and blocks used for workholding purpose.

The use of magnetic chucks for workholding has become a popular option in manufacturing facilities globally. The goal is simple. Hold the blank, casting, or forging to be machined with enough grip to allow milling, turning, drilling, or grinding operation.

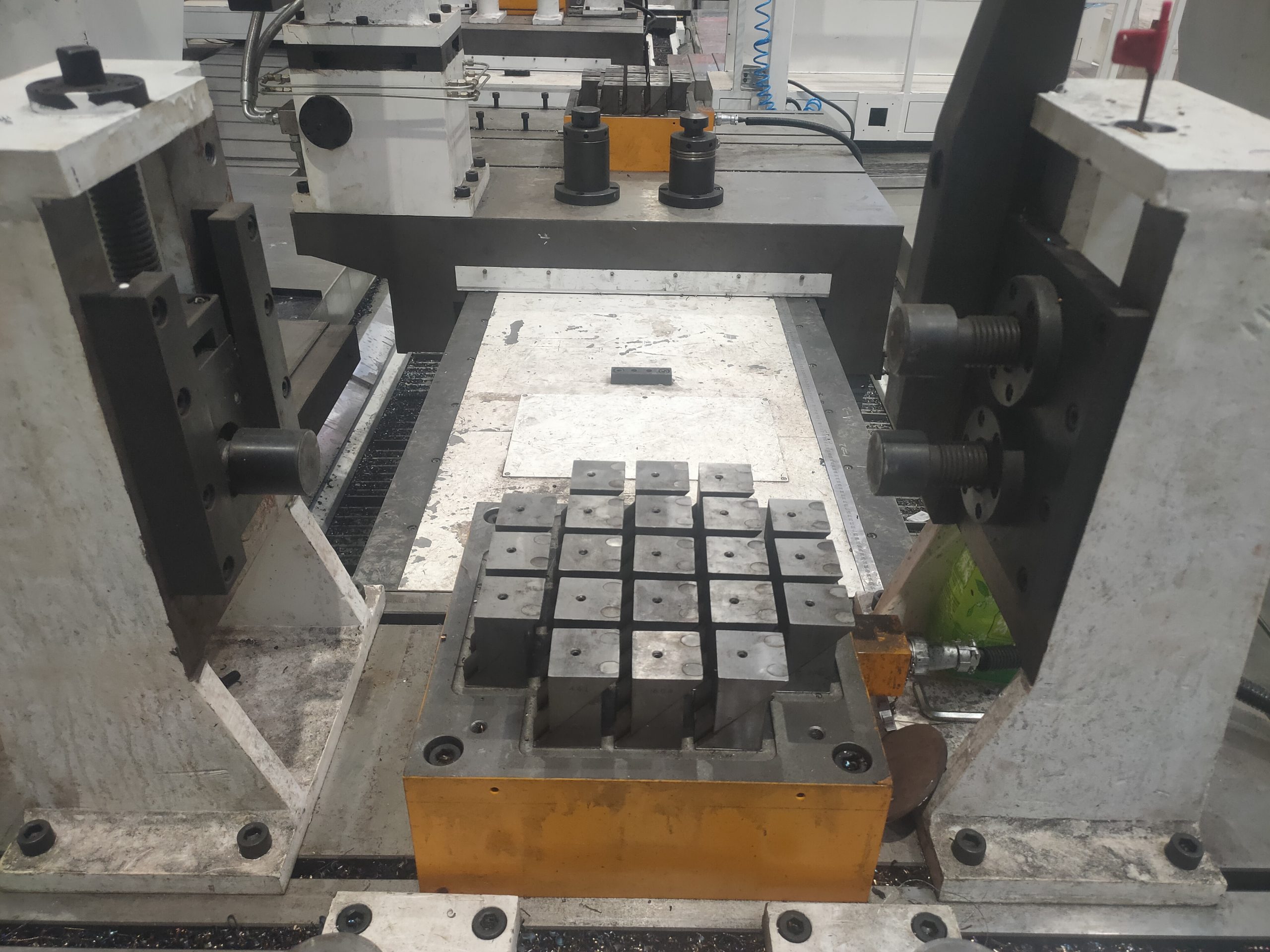

Take a look at the above picture, we can see that the part to be held for machining is very large and irregularly shaped. In this machining center, 3 machines were configured to perform the hole boring work on the body structure of excavator engine rocker arm.

Each machine was equipped with a magnetic chuck. On each surface of magnet chuck was installed with 21pcs of chuck blocks.

What are magnetic chuck blocks used for?

Chuck blocks can extend the flux path of a magnetic chuck and transfer magnetism from the top plate of the chuck through to the workpiece. They can improve the holding performance for irregular shaped workpieces, without distortion that will be caused by mechanical clamping, while release/clamp time is significantly reduced.

Previously this work shop was using conventional chucking devices such as vise and pinch plate to fixate the workpiece to bore holes on it. Why changes now? There must be problems.

Problems solved by using electro permanent magnetic chucks:

- Easy & fast clamping of workpiece, no manual fixing and pinching, significantly enhance machining efficiency and reduce labor intensity;

- Magnetic chucks with blocks make the workholding job more flexing, which works great for workpieces that has unequal surfaces caused by the welding deformation;

- Can avoid damages & deformations to the surface of workpiece when using vises and pinch plate to hold.

Extra benefits gained with customized EPM magnetic chucks and blocks are obvious:

- More stable clamping & holding avoids the vibration generated by the machining process, and reduces the defective rate of workpiece;

- Boring 3 holes simultaneously significantly increases the production capacity and improves efficiency, when compared with boring 1 hole each time previously;

- Reduced labor cost – one operator can take care of 3 machines now instead of 3 workers required.

As a professional manufacturer of electro permanent magnetic products, HVR MAG offers tailored magnetic clamping solutions for fabricators who want to perform different machining operations. Compared to traditional fixturing methods, workholding magnetic chucks frees up all five sides of your workpiece so you can machine the multiple profiles in once.

With extra magnetic chuck blocks, our magnetic clamping devices can hold all ferrous materials for general milling, turning, grinding, or other types of CNC machining center operations. Visit our website www.hvrmagnet.com to learn more about our solutions for magnetic workholding, or contact us to get a free solution and quotation.