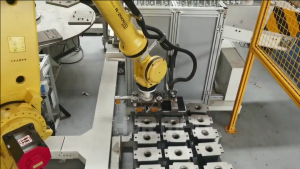

The EOAT gripper is an essential accessory for industrial robots. EOAT means end of arm tooling. It is the robot’s end effector. It can work with robots in many tasks such as handling, sorting, palletising, packaging, quality inspection and welding. It can perform repetitive tasks accurately and with high reliability. Many companies are now installing process robots and the associated EOAT gripper to replace highly repetitive but simple manual movements.

The EOAT gripper is available in various types, mechanical, pneumatic, vacuum and magnetic. They are suitable for different workpiece materials and shapes. However, the magnetic gripper is the most popular in industries such as automotive manufacturing, mechanical engineering and rail transportation where steel is used extensively.

About the magnetic gripper

Magnetic EOAT gripper uses a built-in magnet to attract magnetically conductive material. The great advantage of this method is its convenience, as long as there is sufficient contact area between the magnet and the workpiece, it can be easily picked up. There is no need to worry about scratches or deformation caused by too tight a grip. It is also basically universal in the case of several workpiece sizes with a small difference in weight.

However, there are two types of magnet: electromagnetic and permanent. The more obvious disadvantage of the electromagnetic EOAT gripper is that it needs to be powered all the time and the copper coils inside accumulate a lot of heat after prolonged use. This is very dangerous because the high temperature causes the magnet to become less magnetic and the workpiece to fall off easily. The permanent magnet does not need to worry about high power consumption and heat generation, but the simple permanent magnet control method is not intelligent enough, which can affect the robot’s efficiency.

Is there a magnetic gripper that can be quickly and intelligently controlled by industrial robots? Of course there is, and it is the electro-permanent magnet EOAT gripper. HVR MAG has specialised in the industrial application of electro-permanent magnet technology since its inception. Our electro-permanent magnetic grippers are the perfect partner for your industrial robots.

The EOAT gripper made of electro-permanent magnets has the following advantages

Energy saving

The magnetic field of an electropermanent magnet comes from the same rare earth permanent magnet material inside as a permanent magnet. The current acts as a switch for the magnetic field of the permanent magnet material. In a gripping and releasing cycle, the current is only used at the moment of gripping and releasing. These two actions correspond to the magnetising and demagnetising actions of the electropermanent magnet and take only 0.2 to 2 seconds each. This saves up to 95% of electrical energy compared to the use of an electromagnet gripper.

Safety

It has already been mentioned that an electromagnet gets hot when it is used for a long time. This is because the copper coil inside has a resistive effect. The electric permanent magnet gripper, on the other hand, also has coils inside, but they are energised for a very short time and do not accumulate much heat. It is therefore safer.

Strong magnetic pull

The magnetic suction force of the electro-permanent magnetic gripper can reach up to 16 kg/cm², which is very strong. So even when handling larger workpieces, we can design the EOAT gripper in a smaller size.

Maintenance free

The electropermanent magnet gripper is made entirely of high quality steel and is water and oil resistant. The magnetic poles are fixed inside the steel and there are virtually no loose or falling parts. Robust and durable. Only the magnetic pole surfaces need to be kept clean.

HVR MAG wants more factories to experience the benefits of industrial automation, and we will provide you with high quality electro-permanent magnetic grippers and sincere service. If you need a customised EOAT gripper, please contact us at:export@hvrmagnet.com