This article mainly centers around the definition of end effector, its types and applications in robotics.

What Is An Robot End Effector?

In robotics, it refers to any of various tools that can be mounted at the end of a robotic arm and that are used to interact with or manipulate objects. It’s the part of the robot that interacts with the environment, which is why it’s also called the “business end” of every robot.

The structure of it depends on the task the robot will be performing and the object the robot will be handling.

In manufacturing, a robot arm can accommodate only certain tasks without changes to its end effector’s ancillary hardware and/or programming. If a robot needs to pick something up, a type of robot hand called a gripper is the most functional end effector. If a robot needs to be able to tighten screws, however, then the robot must be fitted with an end effector that can spin.

Common Types of End Effectors Used in Manufacturing Include:

- anti-collision sensors

- brushes

- cameras

- cutting tools

- drills

- grippers

- magnets

- sanders

- screw drivers

- spray guns

- vacuum cups

- welding guns

Common Applications of End Effector

- Pick & Place. Pick & place tasks are those where an object needs to be picked up and placed in a different location. …

- Machine Tending. …

- Packaging & Palletizing. …

- Assembly. …

- Quality Testing & Inspection. …

- Surface Finishing.

Typical Cases of Magnetic Grippers in Robotics

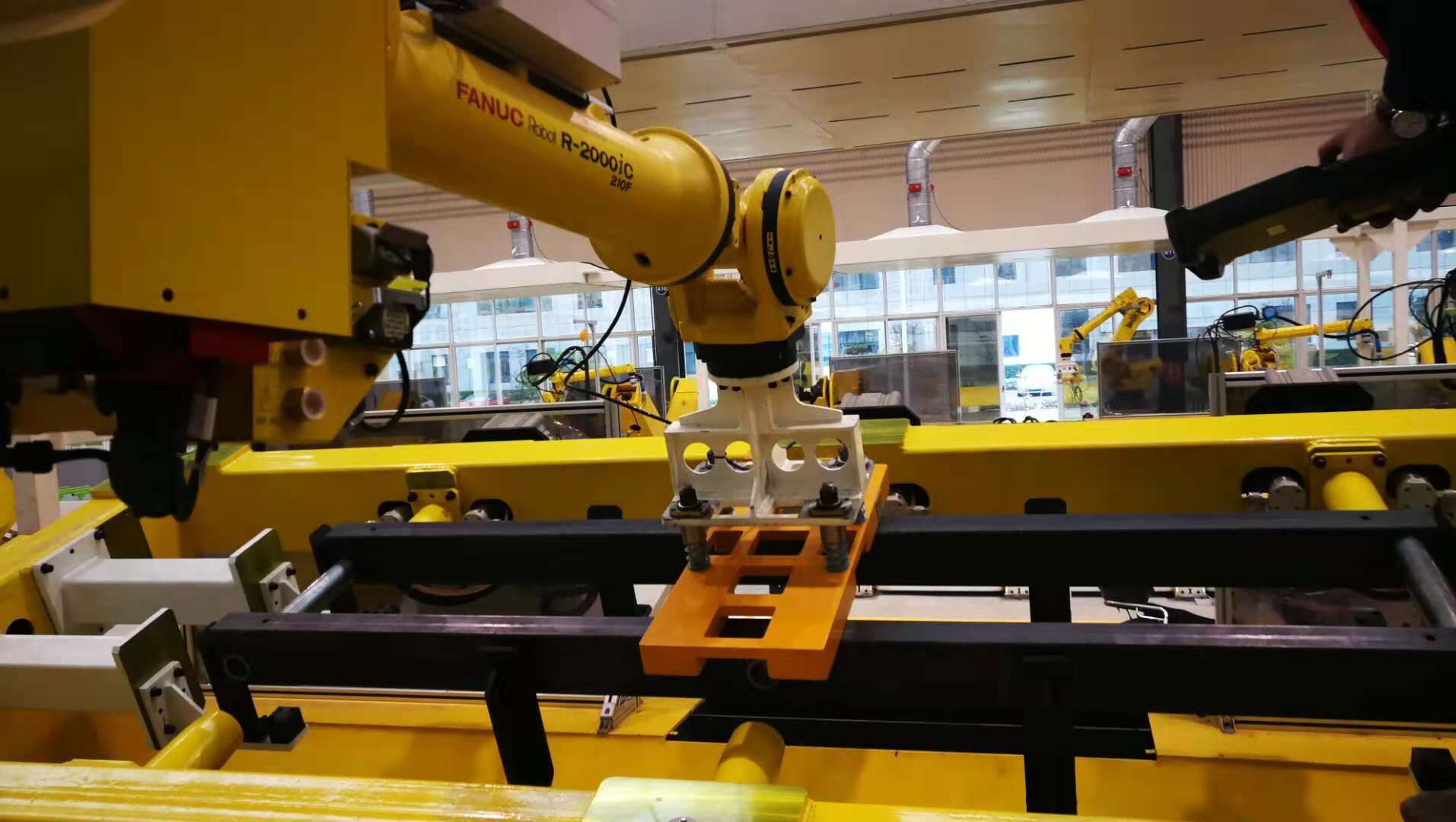

The end effectors used on above FANUC industrial robots are called grippers(magnetic type).

HVR MAG can tailor design and manufacture magnetic end effector for various robots, like robotic arms, cobots, gantry robot systems, etc. See more applications, welcome to visit our website page:https://www.hvrmagnet.com/category/magnets-for-industiral-automation-5.html