Robotics has revolutionized manufacturing processes by automating repetitive tasks and improving production efficiency. One of the crucial components of a robot is the gripping system, which is responsible for grasping and releasing objects. There are different types of robot grippers available in the market, including electromagnetic robot gripper and electric permanent magnetic grippers. In this article, we will discuss the differences between these two types of robot grippers.

Electromagnetic Robot Gripper

An electromagnetic robot gripper uses an electromagnetic coil to generate a magnetic field that attracts ferromagnetic objects. In an electromagnetic system, a magnetic field is generated by passing an electric current through a coil of wire. The coil is made up of a conductor, usually copper or aluminum. Wound around a core made of a ferromagnetic material, such as iron. The magnetic field generated by the current passing through the coil interacts with the magnetic field of the core, creating a strong magnetic force.

The strength of the magnetic force depends on several factors. Including the magnitude of the current passing through the coil, the number of turns in the coil, and the properties of the core material. By varying these factors, the strength of the magnetic force can be controlled.

Electromagnetic systems are used in a wide range of applications, including electromagnets, relays, solenoids, and generators. They are also used in many industrial applications, such as magnetic clamping systems, magnetic lifting systems, and magnetic separators.

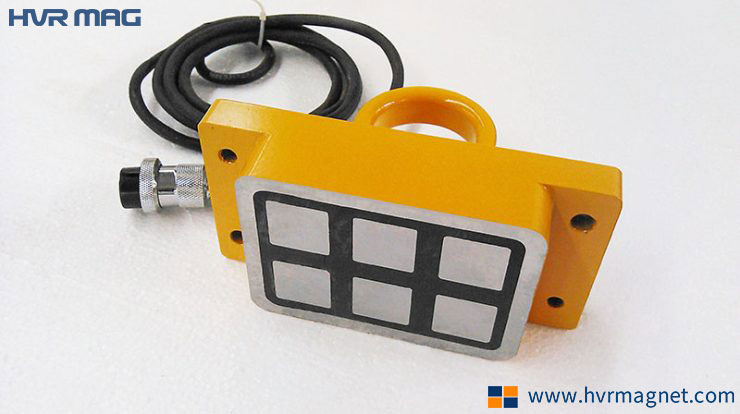

Electric Permanent Magnetic Robot Gripper

An electric permanent magnetic robot gripper uses a permanent magnet to generate a magnetic field instead of an electromagnetic coil. The permanent magnet is made of a ferromagnetic material that retains its magnetic properties even when the current is turned off.

The main difference between these two types of robot grippers is the way they generate the magnetic field. Electromagnetic grippers require a continuous supply of electric current to generate the magnetic field. While electric permanent magnetic grippers do not require any external power source. This means that electromagnetic grippers are more power-hungry than electric permanent magnetic grippers, and require a power supply to operate.

For this reason, EPM gripper is more suitable than an electromagnetic robot gripper when long operating times are required. Because it uses only 5% of the power of an electromagnet. You can save a lot of money on energy costs. An additional benefit is that the electro-permanent magnet does not get hot over a long period of time and its magnetism does not deteriorate. It is also safer than using an electromagnetic machine gripper.

Conclusion

Overall, using an electro-permanent magnet gripper is more energy efficient and safer than using an electromagnetic robot gripper, while the difference in their efficiency is not significant. This makes the electro-permanent magnet gripper the more recommended choice, as it guarantees efficient workpiece handling while reducing running costs. Electromagnets, on the other hand, have the unique advantage of gripping steel with a large air gap and are suitable for sorting scrap, for example. If the electromagnetic robot gripper is used to handle thin steel, it is also very easy for the workpiece to become magnetised.

As a specialist manufacturer of electropermanent magnetic grippers, HVR MAG has developed three ranges of magnetic grippers: Permanent Electro Magnetic Gripper for Articulated Robot, Permanent Electro Magnetic Gripper for Gantry Robot and Welding Magnets for Automation. These are made from electropermanent magnets and are efficient, fast, safe and energy-saving. And they can be customised in terms of size and magnetic strength. Do not hesitate to contact us.