The electromagnetic chuck is a clamping device used on machine tools. It can be used instead of clamping plates and bolts to fix the workpiece to be ground. They can be divided into electromagnetic chucks for grinding machines. Electromagnetic chucks for milling machines and planing machines. The traditional electromagnetic chuck uses a coil to generate magnetism. The electromagnet, which consists of a coil and a core, is the main part of the electromagnetic chuck. Its application has significant limitations because it tends to generate high temperatures over a long period of time, which affects the magnetic holding force. A decrease in magnetic force can lead to greater vibration of the workpiece and reduce machining accuracy.

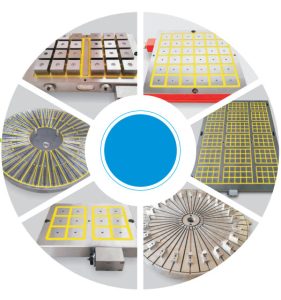

With the development of industry, the demand for electromagnetic tools is increasing and the requirements are becoming higher and higher. Prompting a series of improvements to electromagnetic chucks to enable them to meet the needs of production. As a result, electronically controlled permanent magnetic chucks are now replacing traditional electromagnetic chuck. The magnetic principles and materials of the two are different. The magnetic field of an electronically controlled permanent magnet is generated by the internal rare-earth permanent magnet material. The electric current acts as a magnetic field switch and only uses electricity at the moment of magnetisation and demagnetisation, which is very energy efficient.

The main disadvantages of electromagnetic chuck

- The magnetic strength cannot be adjusted in zones.

- In long-term use, it is easy to heat up and consume a lot of electricity.

Electro-permanent magnetic chuck can solve these problems perfectly.

Advantages of electro-permanent magnetic chuck

Powerful suction

The electro-permanent magnetic chucks have a strong suction force of up to 16 kg/cm². The magnetic force is evenly distributed and adjustable, making it suitable for all types of powerful machining, roughing and finishing operations.

Machining accuracy

The electronically controlled magnetic chucks do not require a constant connection to the power supply to maintain the magnetic force, so no heat is generated during continuous operation. This prevents loosening of the workpiece due to a reduction in magnetic force. The flat, smooth table surface and uniform and stable clamping force improve machining accuracy.

Performance in use

The electro-permanent magnetic chucks are robust and durable. Even after working continuously for more than 20 hours a day, there are no breakdowns. No maintenance is required other than keeping the table clean.

Operational efficiency

The neatly arranged magnetic poles of the electronically controlled permanent magnetic chuck allow fast positioning of the workpiece. 0.3 seconds is all it takes to clamp or release the workpiece, greatly increasing productivity.

HVR MAG is a professional manufacturer of electro-permanent magnetic chuck. We can provide you with high performance products. Feel free to contact us at:export@hvrmagnet.com