CNC Machine and CNC Machining sounds like the same, while actually they’re different. Go through this article to gain a better understanding of the difference between them.

What Does “CNC” Stand for?

Briefly, it is the acronym for Computer Numerical Control. It is an outgrowth of the older term “NC”, which stands for “Numerical Control”. It refers to the idea of controlling machine tools via computer.

What Is A CNC Machine?

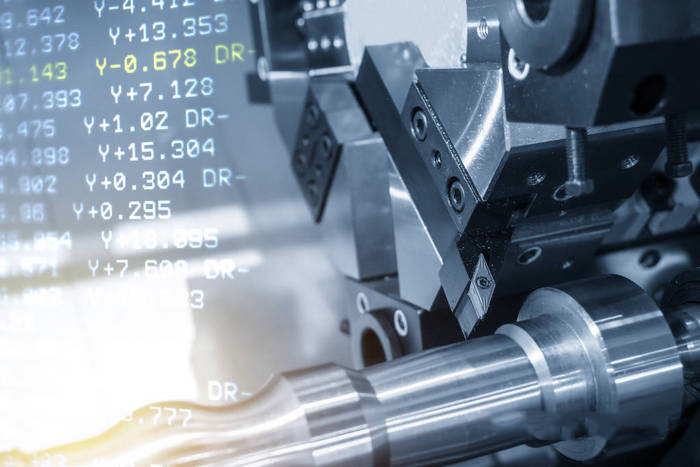

CNC machines are computer controlled machine tools or carving machines. Essentially speaking, they’re machining robots. Before CNC, machine tools were manually controlled by machinists. With CNC, a computer controls servos that operate the machine. NC, and later CNC, allowed for tremendous increases in productivity for machine tools because the machinery could be run automatically without requiring constant attention from their operator.

How Does A CNC Machine Work?

A CNC machine uses a computer which is programmed for cutting of the metal for a particular job as per the requirements. The cutting processes that are to be carried out as well as all the final dimensions are provided as an input via the program. Hence, the computer knows what exactly is to be done and carries out the cutting processes accordingly. CNC machine seems like a Robot, which has to be provided with instructions to produce desired outputs.

What Is CNC Machining?

Lexically speaking, we can tell that it’s different from cnc machine. Machining refers to a PROCESS, while machine is simply a kind of machine. In short, CNC machining is a manufacturing process which typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part.

This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Types of CNC Machining Application

CNC machining uses many different types of devices. Milling, maachine drilling and machine turning operate in various methods, either turning the tools or the material. Workers choose the best method to use based on the required precision of the product and the content used.

Machine turning: Turning is a machining process which employs single-point cutting tools to remove material from the rotating workpiece.

Machine drilling: It employs multi-point drill bits to produce cylindrical holes in the workpiece.

Machine milling: Milling is a machining process which employs rotating multi-point cutting tools to remove material from the workpiece. Machine milling turns the tools around the piece, and the mills can use numerous tools for highly detailed parts.

With the right machine and material for the job, CNC machining can serve a wide range of varied industries. Each of these industries has its own needs, which means not all uses of CNC machining will work for every business.

Want to learn more about milling, turning and other applications, please wait for our last blog.