In the process of manual cutting and welding of steel plates, it is often necessary to move and manipulate the steel plates to the desired position. Using battery powered lifting magnets can provide a fast, efficient and safe way to lift and manipulate steel plates.

Steel Plate Handling in Cutting and Welding

Steel plate handling is an important aspect of cutting and welding processes, and it is critical to ensure safe and efficient handling of steel plates.

Manual handling involves the use of hand tools to move and position steel plates. However, manual handling can be labor-intensive and time-consuming, and there is a higher risk of injury to operators, especially when dealing with heavy or bulky steel plates.

It is important to ensure that the steel plates are properly secured and positioned to prevent slipping, tipping, or falling. Adequate safety measures should be in place to protect operators and equipment from potential risks, such as falling objects or collisions.

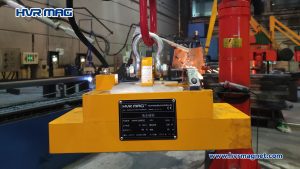

Battery Powered Lifting Magnets

Battery powered lifting magnets are electro permanent lifting magnets with battery supply. These magnets provide a safe lifting solution as they eliminate the need for chains, slings, or hooks, which can be prone to accidents, slippage, or disengagement.

They require power only during the magnetization and demagnetization cycles. Once the magnet is energized, it maintains its magnetic holding force without the need for a continuous power supply, resulting in energy efficiency and prolonged battery life.

Advantages of Battery Powered Lifting Magnets

Battery powered lifting magnets are portable, allowing them to be easily moved to different locations or work areas. This makes them ideal for applications where mobility is required or when materials need to be lifted and transported across various workstations.

They come with a control panel or remote control, allowing operators to easily operate and control the lifting process. They offer flexibility in terms of adjusting the holding force, release timings, and features like magnetic detection and lifting capacity monitoring.

Conclusion

Regardless of the handling method used, it is important to ensure that the steel plates are properly secured and positioned to prevent slipping or falling. It is advisable to choose a high-quality electro permanent lifting magnets to avoid safety issues. A reliable supplier provide repair maintenance services and other after-sale service. For more information, please contact HVR MAG at export@hvrmagnet.com