This article mainly centers around some typical concerns and problems that steel manufacturers have met in loading steel plate for shearing or cutting procedure, and a typical collection of magnetic lifting equipment HVR MAG supplied for various manufacturing workshops.

If your factory has to deal with steel plates every day, what are your concerns when choosing plate handling equipment? Scratches to the surface of sheet, or worrying about a sudden dropping load during the lift? How to ensure that only one sheet will be picked up each time by magnetic lifting equipment, especially for thin sheets? Well, to relieve your concerns, I suggest you finish reading this article.

Lifting with conventional tools like plate clamps or hooks, tends to leave scratches or damages to the surface of sheet. But with magnetic lifting equipment, magnetic attraction force can perfectly solve that problem.

Whether it’s loading for shearing or cutting machine, a very basic requirement for the lifting device is that it loads only 1 sheet each time. Then how to ensure that? Common lifting electromagnets quite often will pick up multiple sheets each time, especially for the thin ones. However, the upgraded type of electro-permanent magnetic lifting system can do precision handling of one sheet in each lift.

Landing Detection Device of Magnetic Lifting Equipment

What is it? It’s an inductive proximity switch and associated cam, mounted on the harp shackle of the hoisting chain, prevents accidental demagnetizing in the air.

What does landing detection mean to the overall safety of steel lifting process?

It means that under no circumstances will the suspended load drop or fall off even an improper operation of DEMAG occur-ed during lifting before the touchdown. Or we can put it in another way, that the load can only be released from the attraction of magnetic lifting equipment when it touches the ground safely and successfully.

Selection of Power Position and Magnet Groups

PICK-UP CYCLE (POWER POSITION)

Depending on the thickness of the steel plate, the force can be adjusted, so that only 1 plate is

guaranteed to be lifted.

Percentage of total force

at PICK UP:

POSITION I = 17%

POSITION II = 25%

POSITION III = 35%

POSITION IV = 55%

SELECTION MAGNETIC MODULES

A corresponding number of magnet modules can be selected via a 4-position switch, depending on the dimensions of the steel plate to be lifted. The possibility to shorten or extend the centre distance between the crossbeams and to select the magnet modules individually, make the HM2 traverses exceptionally flexible in use, even in limited spaces.

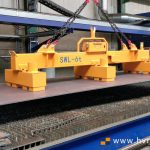

Below is a short collection of HVR MAG’s typical magnetic lifting equipment loading steel plate/sheet for cutting or shearing machine.

Distinctive Features of HVR MAG’s Magnetic Lifting Equipment

✦Remote Controlled: each set of lifting magnets system is equipped with a remote

✦Reduced defective rate of sheet: uniformly distributed strong magnetic force, for scratch-free and tight holding of sheet.(beats clamps/hooks/straps)

✦Flexible lifting solution: selective control of magnet modules, for handling steel sheets of different lengths (beats vacuum cups)

✦Reduce safety hazards: no dropping load even in a sudden power outage, due to property of electro permanent magnets.(beats lifting electromagnets)

✦No moving parts inside, barely no maintenance; easy to operate.

Why Should You Choose Steel Magnetic Lifting Device from HVR MAG?

•To Improve Steel Handling Efficiency – magnet lifting spares the need of manual separation of metal sheet.

•To Eliminate Safety Hazard – strong magnetic clamping force on plate ensures no dropping of plate, even in a sudden power outage.

•To Preserve Sheet Surface – uniform magnetic lifting force leaves no scratches/marks on the surface of plate.

•To reduce Labor Intensity – the remote requires only one worker to operate.

Manufacturer & Supplier of Magnetic Lifting Equipment for Steel

HVR MAG offers CUSTOMED steel plate loading solutions for shearing and cutting machines. Also we can tailor design both loading & unloading solution for cutting system.

Featured with Superior Safety and Energy Saving, our magnetic lifting equipment is specifically designed by our engineers through mutual communications with clients, to best fit their lifting needs and requirements. Contact us for further information.