Electro-permanent lifting magnet is widely used for handling ferrous materials, but there are still many technical problems to be solved in the specific application. Today we would like to show you how to choose the right lifting magnet according to the shape of the steel materials.

Let’s start with the steel plate category. Steel plates look very easy to lift because they are large and flat. But it is not as easy as it seems, because we have to pay attention to the deformation of the steel plates and the adhesion between them during the lifting process. Therefore, we have designed different lifting magnets for different thicknesses and sizes of steel plates.

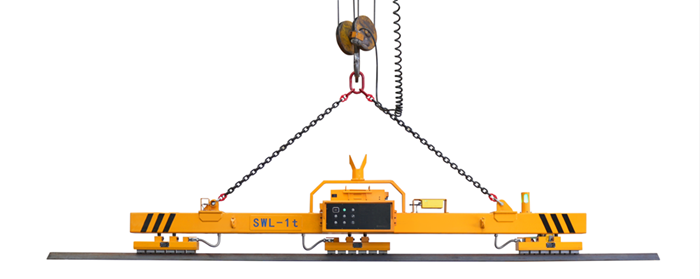

Lifting magnet for thick steel plates

The HM1 is specially designed for lifting medium thickness steel plates (≥6 mm). Medium-thick steel plates are not so easily deformed, so the magnetic modules are fixed to the crossbeam, which ensures that the plates are evenly affected. The HM2 series of telescopic beams can be selected to suit the length of the steel plate to be lifted. The magnetic modules can be controlled in groups.

For thin steel plates

HM3 is designed for thin and long steel plates that are very susceptible to deformation during lifting. Instead of fixing the magnetic block to the beam, we use a suspension method that allows the magnetic module to better adapt to the angle of the plate. This ensuring stability and safety during lifting.

For vertical lifting

The HM4 series is suitable for situations where a steel plate needs to be lifted sideways. If you need to rotate or tilt steel during handling, take a look at this model. The magnetic block can be tilted from horizontal to vertical up to a maximum angle of 90 degrees. It is also possible to lock the end stop and switch to a flat suction position.

For steel plate cutting line

Another situation is how to quickly sort the parts after the whole sheet has been cut. If you need to solve this problem, our HM5 series is highly recommended. The small size of the individual electro-permanent magnetic modules, combined with the intelligent detection and zoning of the system, allows a number of small cut pieces to be picked up at once. It is also possible to pick up a complete steel plate.

All of the above models are designed to lift individual steel plates in a single operation. Sometimes it is necessary to lift more than one plate at a time and of course we have an option for that. This is the HM6 series. The HM6 series is currently capable of lifting 6 sheets of 6mm steel at a time and 2 sheets of 20-25mm steel at a time.

Our advice is to choose the most suitable lifting magnet according to your actual working conditions. HVR MAG will provide you with professional solutions. Please do not hesitate to contact us at:export@hvrmagnet.com