It’s commonly acknowledged that the automotive and vehicle industry and a large volume of the steel sheets and cast and finished components produced are supplied to this industry. Let’s take an inside look at it.

Why steel is used in automotive industry?

Steel is very hard and strong, and has a very high strength to weight ratio. All these properties make it suitable as a material for car bodies.

How is steel used in cars?

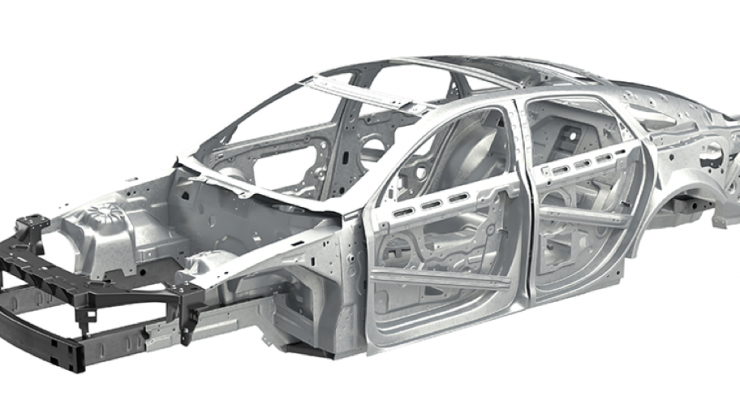

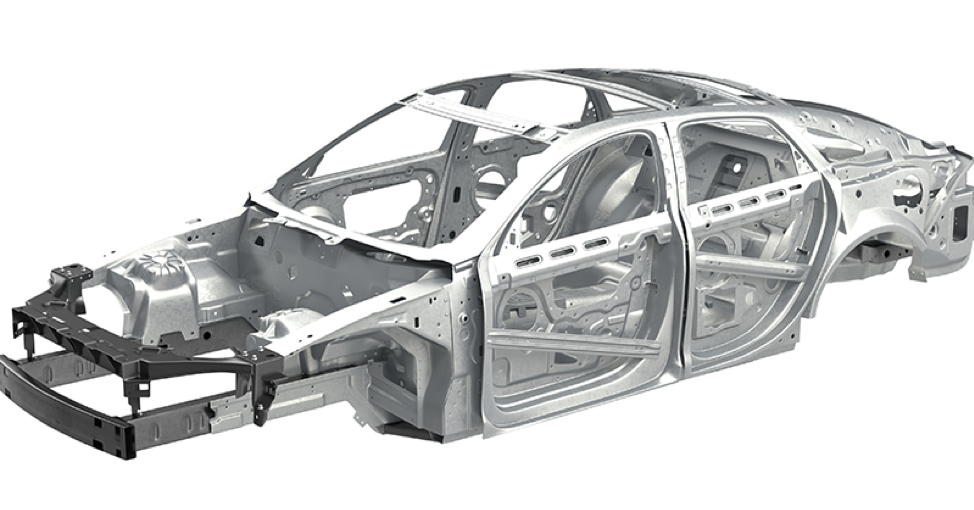

In cars, steel is used to create the underlying chassis or cage beneath the body that forms the skeleton of the vehicle and protects you in the event of a crash. Door beams, roofs and even body panels created during auto manufacturing are made of steel on most cars today.

There are several common uses for steel in an automotive vehicle. Most of this steel is found in the skeletal body of the vehicle, often called the “body in white,” which is the foundation from which the rest of the vehicle is created.

The types of steel used in the automotive industry can be anywhere from stainless steel, high-strength steel, high-carbon, low-carbon, or galvanized steel for body panels. These types of steel are used in the production of various vehicle and engine components.

A mechanically operated press drives a punch against steel sheet, forcing it into a simple die with enough pressure to produce a permanent change in the metal’s shape.

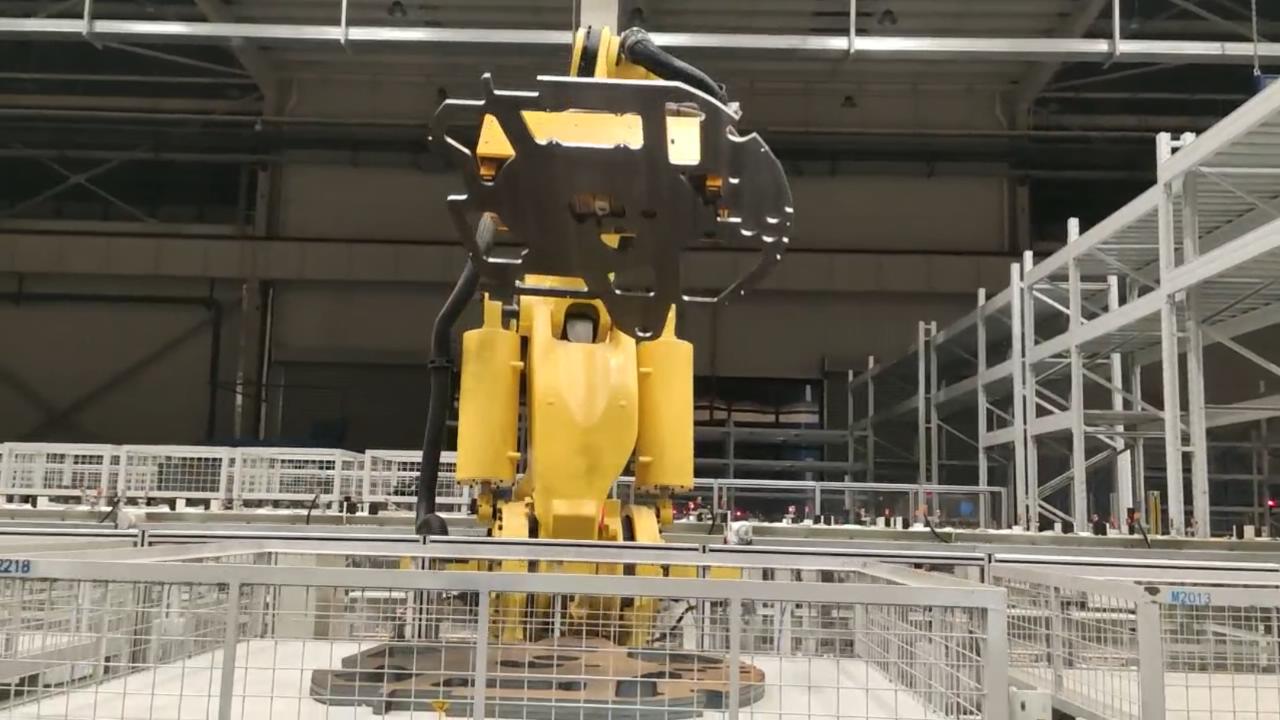

Whatever the usage of steel sheets are, they’ll need to be moved/transferred from one place to another, which requires a set of efficient plate handling equipment. HVR MAG’s lifting magnets with spreader bar, magnetic grippers used for robots, are ideal solutions for steel handling purpose.

How Can Steel Sheets Be Handled for Different Processes?

Metal forming, cutting, and welding, are the most commonly used manufacturing processes of making a vehicle.

- Below-the-hook lifting: this type of steel lifting equipment is mainly used for loading steel sheets onto cutting machines, or for unloading the long cut sheet off the uncoiling line. Usually there are many different lifting tools for choice, however, in order to protect the surface of sheet steel from scratches, appropriate lifting devices are limited. Magnetic lifting is a good solution for that.

- Robotic handling: unload the punched steel part off the stamping press, or unload the cut pieces off the cutting table, and transferring them into further welding process. This would inevitably entail the use of magnetic grippers used for robots, to perform the pick and place of steel sheet parts across different lines.

As the automotive industry continues to grow globally, the demand of steel sheets is expected to increase accordingly. Under that circumstances, we can foreseen a growing broad of applications of magnetic solutions and robotic automation in automotive industry.