Steel plate magnetic lifter is widely used in the metalworking, construction, shipbuilding, automotive and mechanical engineering industries. With the use of steel plate magnetic lifter, these industries can increase the efficiency of steel plate handling while improving safety during operations.

However, with the development of the energy sector, the use of steel in the energy industry has increased significantly. The demand for efficient handling of steel in the energy sector is therefore increasing. HVR MAG had build a 55 tonne steel plate magnetic lifter for a company specializing in offshore wind turbine foundations few months ago. It can handle steel plates from 45 to 120 mm thick. It is also equipped with a telescopic beam which allows it to handle a wide range of steel plate sizes.

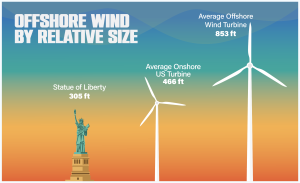

Recently, we have completed the manufacture and testing of a 75 tonne steel plate magnetic lifter. Which will also be used in the offshore wind industry. Why does the offshore wind industry need such a large steel plate lifting magnet? Because offshore wind turbines are much larger than onshore wind turbines. Also, the metal used in offshore foundation columns has to be more resistant to corrosion. As a result, the steel plates used in the offshore wind industry are often very large and heavy. This requires more powerful steel plate handling equipment.

Examples of steel plate magnetic lifter in the offshore wind power industry

Lifting and positioning wind turbine components: Steel plate magnetic lifter can be used to lift and position heavy wind turbine components. Such as towers, nacelles, and blades. The magnets can be attached to cranes or other lifting equipment. Allowing for safe and efficient movement of materials on the construction site.

Installing foundations: Steel plate lifting magnets can be used to install the foundations for offshore wind turbines. The magnets can be used to lift and position steel plates and other components. Allowing for accurate and efficient installation of the foundation.

Maintenance and repair: Steel plate lifting magnets can be used to lift and move heavy components during maintenance and repair work on offshore wind turbines. The magnets can be attached to robotic arms or other equipment, allowing for precise and efficient movement of materials in difficult-to-reach areas.

What makes HVR MAG magnetic lifter so powerful?

Thanks to our electro-permanent magnet technology. It is safe, efficient, powerful and energy saving. The working principle of electro-permanent magnets is to use Alnico and NdFeB magnets, the most powerful magnetic of all magnets available, as the source of the magnetic field. And then use an excitation coil to control the direction of the magnetic field. As a result, the electro-permanent magnet only requires electricity during magnetisation and demagnetisation, and no electricity is used during the transport of the steel plate. As a result, a powerful steel plate lifting magnet can safely and efficiently handle steel plates weighing up to 75 tonnes.

If you are looking for a reliable manufacturer of steel plate magnetic lifter, please do not hesitate to contact us.