Milling clamps are tools used to hold the workpiece in place on the machine. There are various types of milling clamps, but their common purpose is to ensure that the workpiece is always well held in the machining position during the process and to guarantee machining accuracy.

Two principles of workpiece clamping

- The workpiece must be held in place to avoid distortion, vibration or even ejection.

If the workpiece is unevenly stressed, or if it is a very thin piece of material, it may deform under clamping pressure. This may cause it to pop out of the fixture under the pressure of machining. This can cause injury to workers and equipment.

- You must ensure that the workpiece has sufficient machining space

Always check that the tool has sufficient travel and space to run when clamping, and change the clamping method if the fixture or workpiece is too large. If the fixture is blocking the machined part of the workpiece, adjust it promptly.

3 types of milling clamps

To get the best out of your milling machine, you need an effective and safe way to secure your workpiece to the table of your milling machine. Did you know that there are several milling clamps to secure your workpiece for drilling or milling?

Milling clamps such as nuts & studs

You can use bolts and nuts to clamp the workpiece directly to the table. This should be done with care to avoid damage to the machine table. Small imperfections such as metal shavings or burrs can make the workpiece or table surface uneven and lead to machining deviations. Therefore, if you decide to fix the workpiece directly to the table, place a sheet of smooth material in the middle to protect the table.

There are many sets of milling clamps on the market. They enable relatively easy alignment and fixing in the T-slots of the table. By using different sizes of clamps, you can achieve a wide range of workpiece sizes. However, the clamping forces in this way are not sufficiently uniform and they tend to leave scratches.

Vise

Vise is available in plain vise, swivel vise and all-steel vise. All have a tongue or locating key on the underside of the vise to facilitate correct positioning in the T-slot on the drill press table. The vise will hold the force more evenly than a bolt-on, but will still have problems with scratches etc.

Chucks

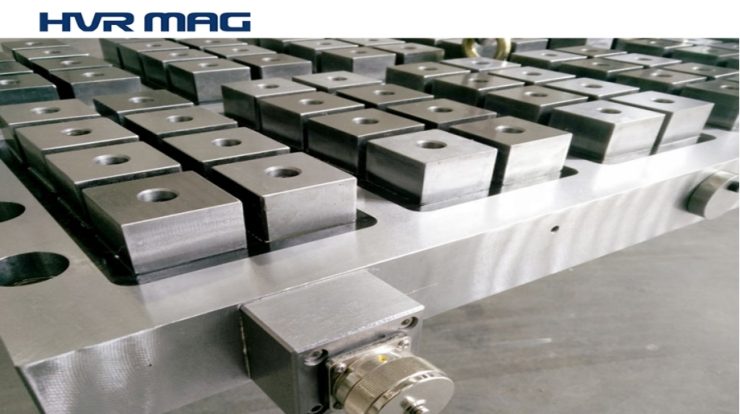

The most widely used chucks today are magnetic chucks. The advantages of magnetic chucks are obvious. All you have to do is place the workpiece in the right place and then either switch on the power or pull down the handle to attach the workpiece to the magnetic chuck. This is very easy to operate and the clamping and speed is very fast, taking only a few seconds.

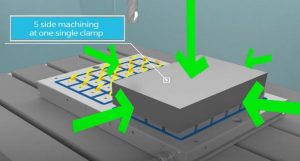

Mounting the magnetic chuck on the machine table ensures that the workpiece is perfectly parallel to the table. The chuck only attaches to the underside of the workpiece, making it easy to work on 5 sides. Full face clamping ensures that the workpiece is clamped evenly throughout, without distortion or scratches.

HVR MAG is a specialist manufacturer of electro-permanent magnetic chucks. The electro-permanent magnet is 95% more energy efficient than electromagnetic. This is because it only requires an electric current to switch the internal permanent magnet material on and off. It only uses electricity at the moment of demagnetisation. With a magnetic force of up to 16 kg per square centimetre, EPM ensures that workpieces are held securely in place. The magnetic field is small and does not penetrate to the surface of the workpiece, so the tool will not be magnetised.

For more information on magnetic milling clamps, please visit the product page or contact us.