Gripper magnets are magnets that are used as grippers for robots. Magnets have a natural advantage when handling ferrous workpieces and the use of magnets on robot grippers is now very common. There are currently 3 types of gripper magnets, pneumatic, electromagnetic and electro-permanent. Are there any differences in performance between them?

3 types of gripper magnets have something in common:

Firstly, they all have the ability to grip flat, round or irregular parts or perforated sheets. This is determined by the principle of the magnet: within a certain weight range, any ferrous workpiece can be gripped easily. Of course, there must be sufficient contact area between the surface of the workpiece and the magnet.

Another thing they have in common is that they are both very efficient, taking less than a few seconds to grip the workpiece. The speed at which the workpiece is released is also very fast. This means that single work cycles can be significantly accelerated with gripper magnets. This will undoubtedly increase the efficiency of your factory’s automated production.

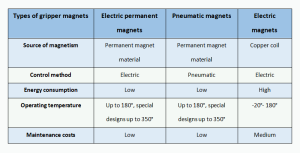

They differ as follows:

As we can see, the electromagnet works on the principle of electricity generating magnetism. So it needs to be constantly energised during operation, which consumes a lot of power. The coil will accumulate a lot of heat after a long period of energisation, which in turn will lead to a reduction in magnetism. Therefore, the safety and stability of electromagnets are not as good as pneumatic magnets and electric permanent magnets. Electromagnets also have a large magnetic field range, which can lead to sticking or residual magnetism when gripping thin workpieces. Electromagnets are recommended for workpieces with a large air gap.

Pneumatic and electric permanent gripper magnets work in basically the same way. The main difference is the method of control. Pneumatic permanent magnets require an external cylinder and air reservoir, as well as wiring to connect the cylinder to the magnet. The circuitry of the EPM can be plugged directly into the control circuit of most robots and is very simple in design. In comparison, the maintenance cost of an electric permanent magnetic gripper is lower than that of a pneumatic magnetic gripper. And the electric control is more intelligent than the pneumatic control. HVR MAG’ EPM gripper can be designed with a demagnetisation function.

These are the commonalities and differences between the 3 types of gripper magnets. If you need a safe, energy-efficient, maintenance-free gripper magnet with the simplest of controls, there is no doubt that an electro-permanent magnet gripper is the most recommended.

HVR MAG can design and manufacture high quality electro-permanent magnetic grippers for you, please contact us at: export@hvrmagnet.com