DYCX Series Electro Permanent Magnetic Chuck is the most ideal method to shorten clamping cycle and save clipping time when user meets the clamping requirement. Within 2 seconds this smart device can safely clamp work piece.

Advantages:

Permanent Safety

Electro permanent magnet is intrinsically safe being not affected by any electrical power failure.

Efficient and Practical

Super Power Magnetic Force is up to 1600kg/100cm²;

5 sides machining can be done in one cycle;

No obstructed movements of cutters during marching;

One work piece can be finished in one cycle, helping in achieving best machining accuracy and increase efficiency a lot.

High Reliability

All HVR magnetic chuck machined from a solid block of steel, resulting in the highest rigidity

Bayonet Connector

50X50 Magnetic poles series(magnetic force of single pole≥350kg)

|

Type&Data

|

Magnetic pole number

|

Total magnetic force(≤KN)

|

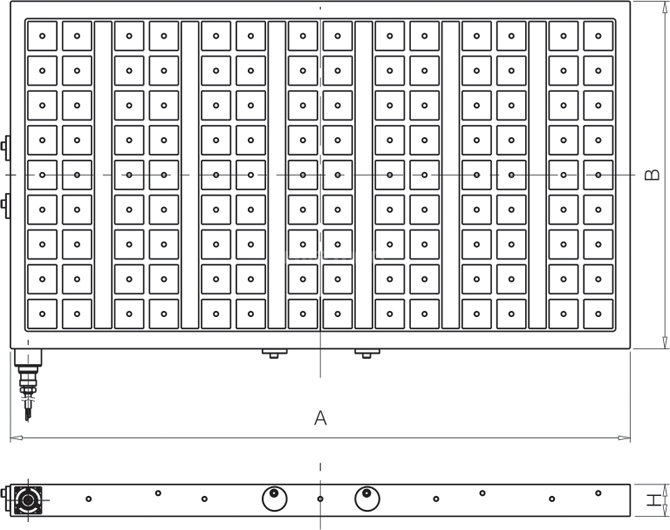

Overall dimension(mm)

|

Weight(kg)

|

||||

|

A

|

B

|

H(standard)

|

H(Strong magnetic)

|

M1(standard)

|

M2(Strong magnetic)

|

|||

|

DYCX-2333P50

|

12

|

42

|

230

|

330

|

56

|

71

|

32

|

40

|

|

DYCX-2348P50

|

18

|

63

|

230

|

480

|

56

|

71

|

46

|

58

|

|

DYCX-2362P50

|

24

|

84

|

230

|

620

|

56

|

71

|

58

|

76

|

|

DYCX-2377P50

|

30

|

105

|

230

|

770

|

56

|

71

|

72

|

94

|

|

DYCX-2392P50

|

36

|

126

|

230

|

920

|

56

|

71

|

86

|

112

|

|

DYCX-2310P50

|

42

|

147

|

230

|

1070

|

56

|

71

|

100

|

130

|

|

DYCX-3033P50

|

16

|

56

|

300

|

330

|

56

|

71

|

40

|

50

|

|

DYCX-3048P50

|

24

|

84

|

300

|

480

|

56

|

71

|

60

|

75

|

|

DYCX-3062P50

|

32

|

112

|

300

|

620

|

56

|

71

|

80

|

100

|

|

DYCX-3077P50

|

40

|

140

|

300

|

770

|

56

|

71

|

100

|

125

|

|

DYCX-3092P50

|

48

|

168

|

300

|

920

|

56

|

71

|

120

|

150

|

|

DYCX-30107P50

|

56

|

196

|

300

|

1070

|

56

|

71

|

140

|

175

|

|

DYCX-4133P50

|

24

|

84

|

410

|

330

|

56

|

71

|

55

|

70

|

|

DYCX-4148P50

|

36

|

126

|

410

|

480

|

56

|

71

|

80

|

100

|

|

DYCX-4162P50

|

48

|

168

|

410

|

620

|

56

|

71

|

105

|

130

|

|

DYCX-4177P50

|

60

|

210

|

410

|

770

|

56

|

71

|

130

|

160

|

|

DYCX-4192P50

|

72

|

252

|

410

|

920

|

56

|

71

|

155

|

190

|

|

DYCX-41107P50

|

84

|

294

|

410

|

1070

|

56

|

71

|

180

|

220

|

|

DYCX-4933P50

|

28

|

98

|

490

|

330

|

56

|

71

|

65

|

85

|

|

DYCX-4948P50

|

42

|

147

|

490

|

480

|

56

|

71

|

95

|

120

|

|

DYCX-4962P50

|

56

|

196

|

490

|

620

|

56

|

71

|

125

|

155

|

|

DYCX-4977P50

|

70

|

245

|

490

|

770

|

56

|

71

|

155

|

190

|

|

DYCX-4992P50

|

84

|

294

|

490

|

920

|

56

|

71

|

185

|

225

|

|

DYCX-49107P50

|

98

|

343

|

490

|

1070

|

56

|

71

|

215

|

260

|

|

DYCX-6033P50

|

36

|

126

|

600

|

330

|

56

|

71

|

80

|

100

|

|

DYCX-6048P50

|

54

|

189

|

600

|

480

|

56

|

71

|

115

|

140

|

|

DYCX-6062P50

|

72

|

252

|

600

|

620

|

56

|

71

|

150

|

180

|

|

DYCX-6077P50

|

90

|

315

|

600

|

770

|

56

|

71

|

185

|

220

|

|

DYCX-6092P50

|

108

|

378

|

600

|

920

|

56

|

71

|

215

|

260

|

|

DYCX-60107P50

|

126

|

441

|

600

|

1070

|

56

|

71

|

240

|

300

|

70X70 Magnetic poles series(magnetic force of single pole≥685kg)

|

Type&Data

|

Magnetic pole number

|

Total magnetic force(≤KN)

|

Overall dimension(mm)

|

Weight(kg)

|

||||

|

A

|

B

|

H(standard)

|

H(Strong magnetic)

|

M1(standard )

|

M2(Strong magnetic)

|

|||

|

DYCX-2242P70

|

8

|

54.8

|

220

|

420

|

56

|

71

|

45

|

55

|

|

DYCX-2261P70

|

12

|

82.2

|

220

|

610

|

56

|

71

|

60

|

75

|

|

DYCX-2281P70

|

16

|

109.6

|

220

|

810

|

56

|

71

|

75

|

95

|

|

DYCX-22100P70

|

20

|

137

|

220

|

1000

|

56

|

71

|

92

|

115

|

|

DYCX-3042P70

|

12

|

82.2

|

300

|

420

|

56

|

71

|

45

|

55

|

|

DYCX-3061P70

|

18

|

123.3

|

300

|

610

|

56

|

71

|

75

|

95

|

|

DYCX-3081P70

|

24

|

164.4

|

300

|

810

|

56

|

71

|

105

|

135

|

|

DYCX-30100P70

|

30

|

205.5

|

300

|

1000

|

56

|

71

|

135

|

175

|

|

DYCX-3922P70

|

8

|

54.8

|

390

|

220

|

56

|

71

|

30

|

40

|

|

DYCX-3942P70

|

16

|

109.6

|

390

|

4200

|

56

|

71

|

65

|

85

|

|

DYCX-3961P70

|

24

|

164.4

|

390

|

610

|

56

|

71

|

100

|

130

|

|

DYCX-3981P70

|

32

|

219.2

|

390

|

810

|

56

|

71

|

135

|

175

|

|

DYCX-39100P70

|

40

|

274

|

390

|

1000

|

56

|

71

|

170

|

220

|

|

DYCX-4822P70

|

10

|

68.5

|

480

|

220

|

56

|

71

|

40

|

50

|

|

DYCX-4842P70

|

20

|

137

|

480

|

420

|

56

|

71

|

80

|

100

|

|

DYCX-4861P70

|

30

|

205.5

|

480

|

610

|

56

|

71

|

120

|

150

|

|

DYCX-4881P70

|

40

|

274

|

480

|

810

|

56

|

71

|

160

|

210

|

|

DYCX-48100P70

|

50

|

342.5

|

480

|

1000

|

56

|

71

|

200

|

160

|

|

DYCX-5822P70

|

12

|

82.2

|

580

|

220

|

56

|

71

|

50

|

65

|

1) Most suitable for machining on medium & small or even rough work pieces;

2) Suitable for drilling and finishing machining on small work pieces.

Work directly with our experienced team to solve your toughest engineering challenges