HVR MAG Magnetic Clamping System for Mold Change are suitable for 50-4000ton injection molding machines to allow for quick mold changeover, resulting in shorter downtime of injection molding machines without any changes to the molds. It provides a uniform mold clamping force act on whole contact surface that allows obtaining good quality parts even with the first mold, drastically reduces mold changeover time (up to 90%) compared to a conventional procedure. A single operator can easily and safely performs the operation, without working inside the machine. The highest standard of eight safety protection measures constructs a real-time protection system.

Features of HVR Magnetic Clamping System for Mold Change

1. Easy to Install

No manual adjustment needed when the mold is fixed in the tapping holes or T-slot.

2. Safety

Only uses electricity in 1-2 seconds of the MAG and DEMAG phase; no need of electricity during the working, which enables it still in the state of working even power off and would not cause any damage to operators; equipped with safe devices like distance detection, temperature detection and location detection.

3. High Efficiency

In general, it only takes 3 minutes to change a mold and the time for changing an oversize mold is decreased from 2 hours to 10min.

4. Maintenance Free

No extra costs on screws, nuts, clamps and other instruments; no distortion to the mold.

5. Simple Operation

Simple and clear

operation penal enables any operator with no operating skills can operate

independently in one minute.

6. Strong Magnetic Force and Safe Devices

Magnetic force can reach 16kg/cm² and will not decrease as time goes.

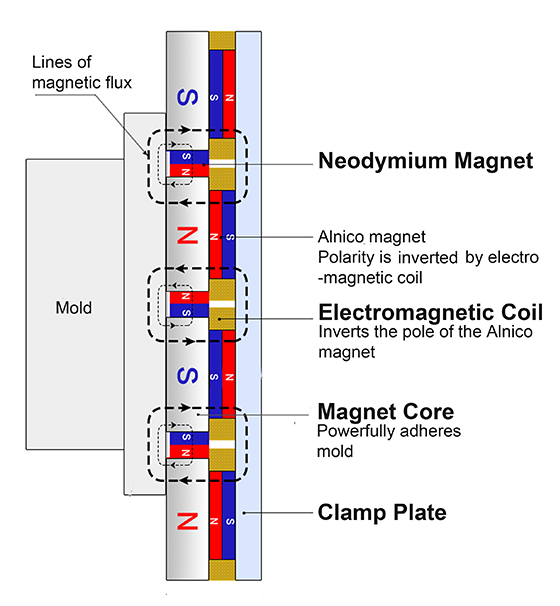

01 Electromagnetic coil energized for 0.5 sec.

02 Pole of Alnico magnet is inverted.

03 Neodymium magnet and Alnico magnet become polar.

04 Magnetic flux of magnets is emitted on the surface of the magnet core. Thus, clamping the mold.

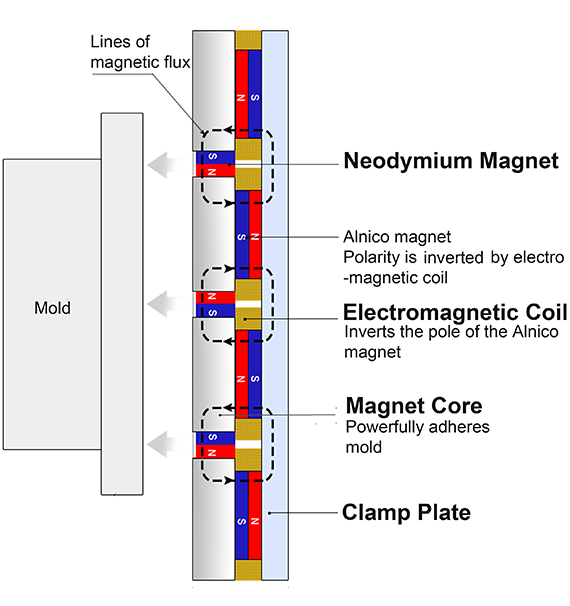

01 Electromagnetic coil energized for 0.5 sec.

02 Pole of Alnico magnet is inverted.

03 Magnetic flux of Neodymium magnet and Alnico magnet is not emitted from the surface of the magnet core. Thus, it unclamps the mold.

Magnetic force remain permanently after magnetization

Save more than 95% of electricity

Save over 90% of mold changing time

IP67 water proof

Magnetic force guarantee an ideal clamping on mold

None spare parts are needed for the platen

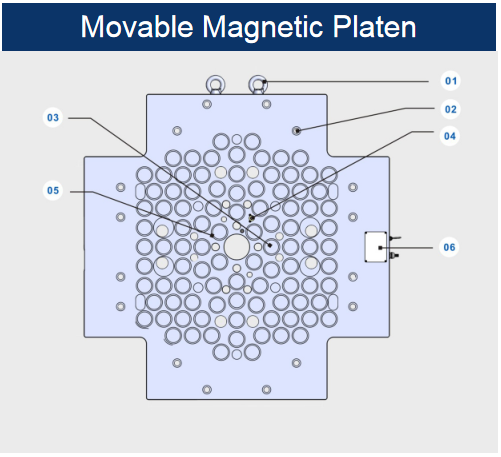

01 Eyebolt

02 Mounting screw hole

03 Mold dislocation detection

04 Distance detection

05 Magnetic flux detection

06 Junction box

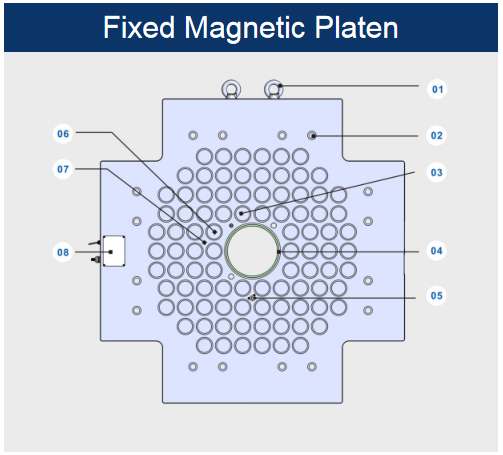

01 Eyebolt

02 Mounting screw hole

03 Mold dislocation detection

04 Locating ring

05 Distance detection

06 Magnetic flux detection

07 Temperature detection

08 Junction box

1.Full metallic surface. High mechanical strength. High protection level.

2. Full-metal push button switch, good controllability, high protection level, safe and stable, more suitable for industrial environment.

3. Proximity Sensor .Magnetic flux contro system .Safety Key that enables the operator to perform simply and clearly.

4.Step –by step help pages with detailed explanation of each operation.

5.An alarm is generated and machine operation is inhibited.

1.Full metallic surface. High mechanical strength. High protection level.

2.Full-metal push button switch, good controllability, high protection level, safe and stable, more suitable for industrial environment.

3.Different access profiles:Machine operator/supevisor/maintenance.

4.Graphic display of run time/mold use/opeator activities.

5.All the external keys are connected with separate I/O signal and main control box. Even if the touch screen or communication fails, the system can carry out normal mold change operation.

Using a key to switch between Mold Changing State and Injecting State. Demagnetization operation will only be valid with the key switched to Mold Changing State and DEMAG button pressed simultaneously. If the key been switched to Injecting State, MAG and DEMAG operation can not be achieved.

HVR MAG Magnetic Clamping System for Mold Change is suitable for 50-4000ton injection molding machines. It is also commonly used in the processes of machining on the shell parts in appliance industries, electronic industries and automobile industries.

Work directly with our experienced team to solve your toughest engineering challenges