In traditinal CNC factory, operating with vices and clamps the workpieces are never completely free and it is necessary to use multiple placements to complete the processing cycle.

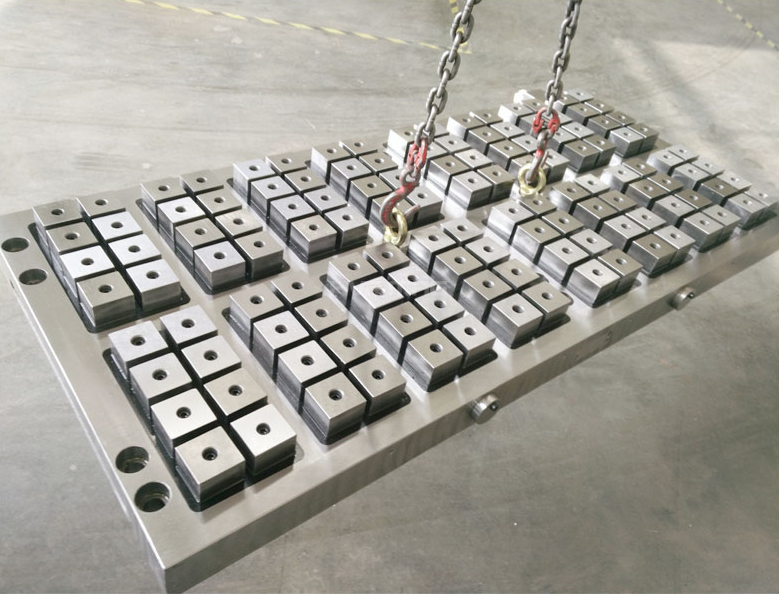

Using HVR Magnetic milling chuck the piece is always free on all 5 faces, allowing the complete machining in a single positioning, improving the working of tools in all operations such as face milling, contouring, through holes and drilling.

Using HVR Magnetic milling chuck, the clamping force is distributed uniformly over the entire contact surface without any compression and deformation of the piece. The absence of vibration allows higher stock removal, better finishing and more strict manufacturing tolerances.

The system is permanent electro, therefore intrinsically safe. Any power outages do not affect the strength of the clamping.

Work directly with our experienced team to solve your toughest engineering challenges